Printable Catalog: Updated 2024-02-20

|

>> Questions - Order Process - PaymentsQuestions -Email correspondence strongly preferred. Email with questions on your particular needs as we have many other parts and services available. If we don't have it we can usually get it or make it. If you need to call, the best time and number is usually 315 478 1229 mornings 10:00 AM - 1:00 P.M. eastern US time. Leave a message if there is no answer as we may be in the shop and cannot get to the phone. If we do not answer or call back try cell # 315 440 6560 and leave a message. There are often periods of 3 - 5 days, especially during the summer, when we are away due to other commitments and the office is closed, though shipping and engine work is continuing at other locations. Although I try to return calls and emails even when out of town, some are replied to when we return. Orders - The easiest way to order is to send an email listing your parts order along with your address and we will reply with information on parts availability and a total price with shipping. Please include information indicating the car model & year with each email, and indicate under "subject " the make of the vehicle and type of part you would like to order. This will keep it from being filtered out as spam. Payments - Payments are normally made by check, credit card, or through Paypal (www.paypal .com) Payments made by Paypal should be made to the account under our email address: jparker3@twcny.rr.com, or we can send you a paypal invoice. We also accept bank wires for larger amounts. |

Supercharger

The Supercharger Kit for Vintage Volvos

The Supercharger Kits described below are unfortunately no longer available.

Described below is the supercharger kit that we developed starting in 2000 and offered for many years after. It was a great project, that demonstrated what could be done and the level of performance that could be achieved from an old Volvo b20 engine. In the future tis possible that we may do a few custom supercharger installations, but this will be on a very limited and exclusive basis. As an alternative, we now offer larger displacement normally aspirated B20 engines that produce more power than superchargers installed on stock engines. Below is the information on the last kits offered, to be used as a reference.

-----------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

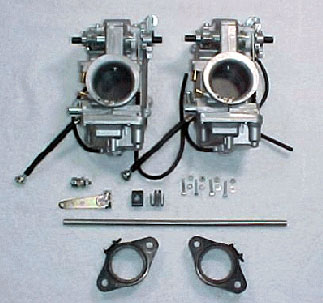

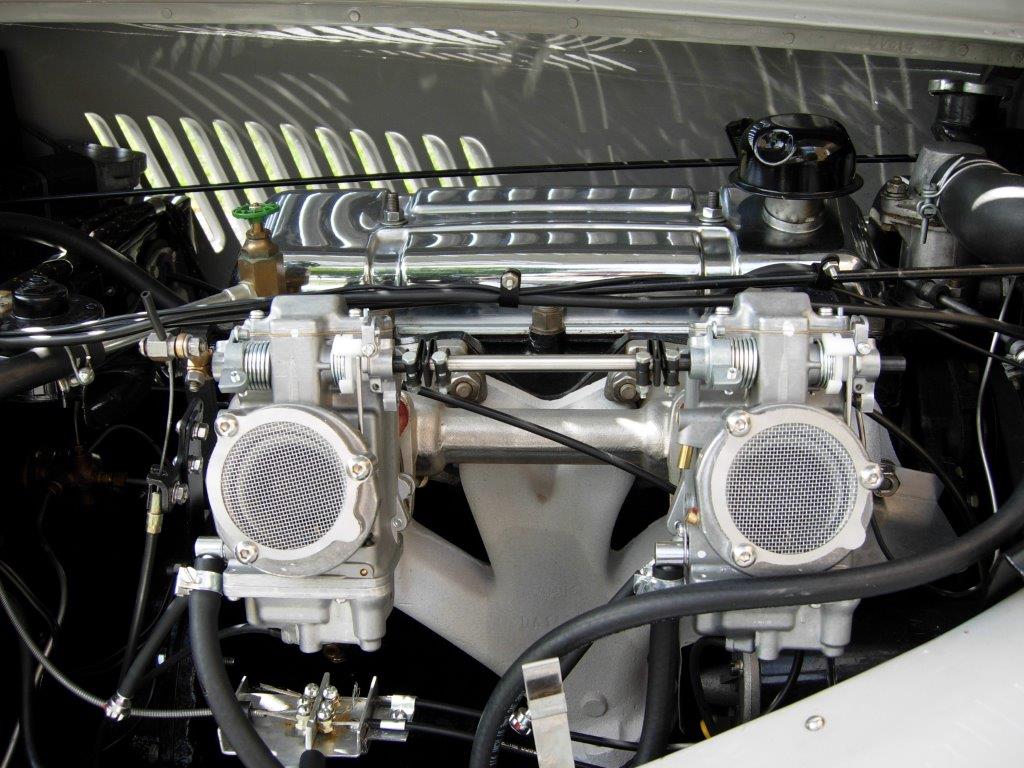

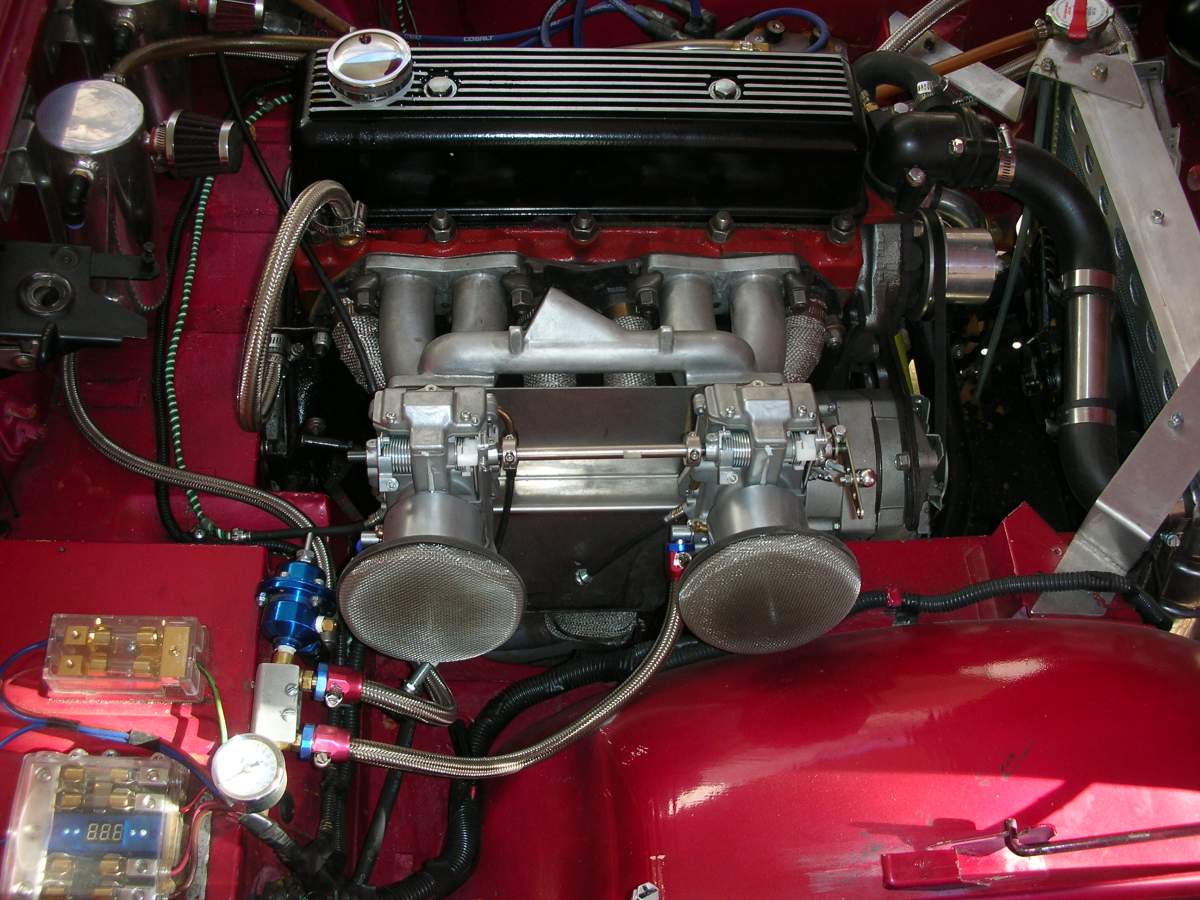

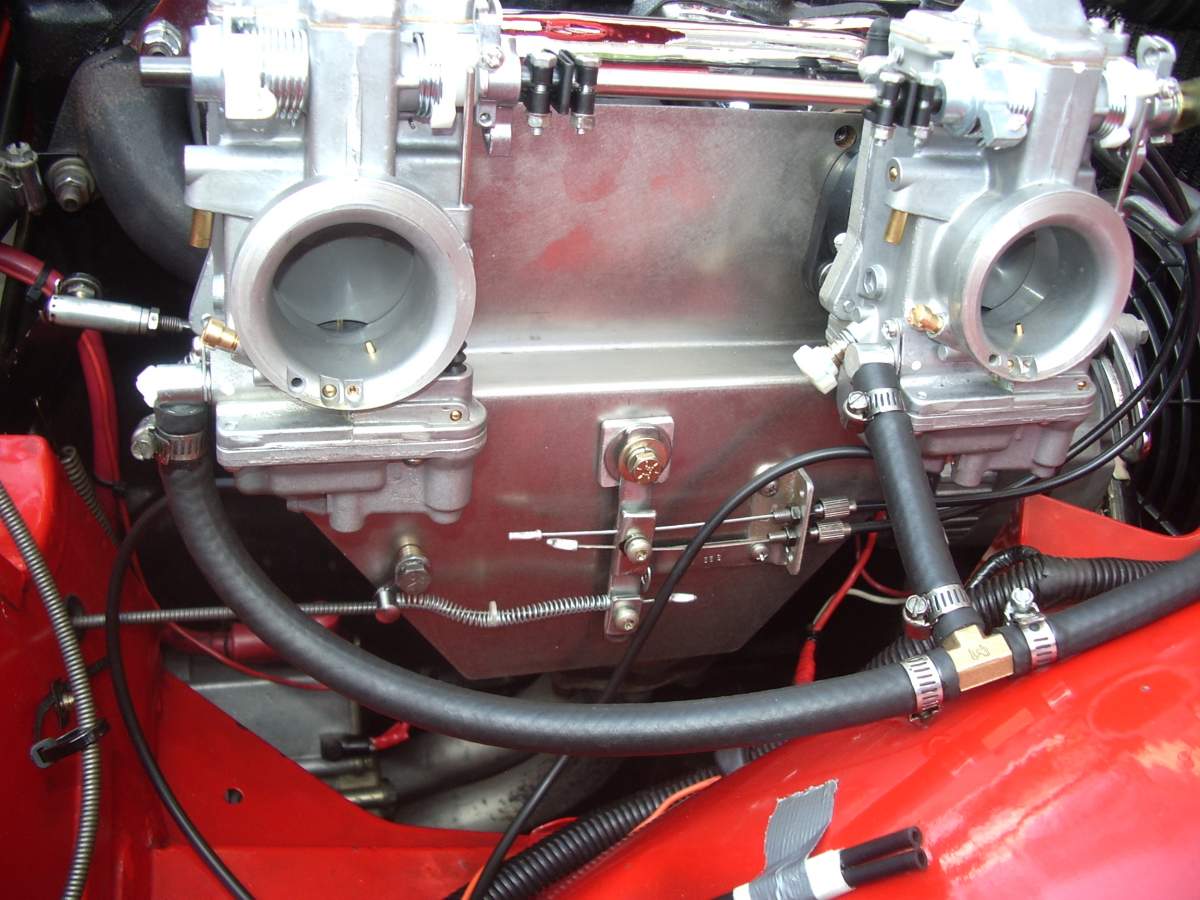

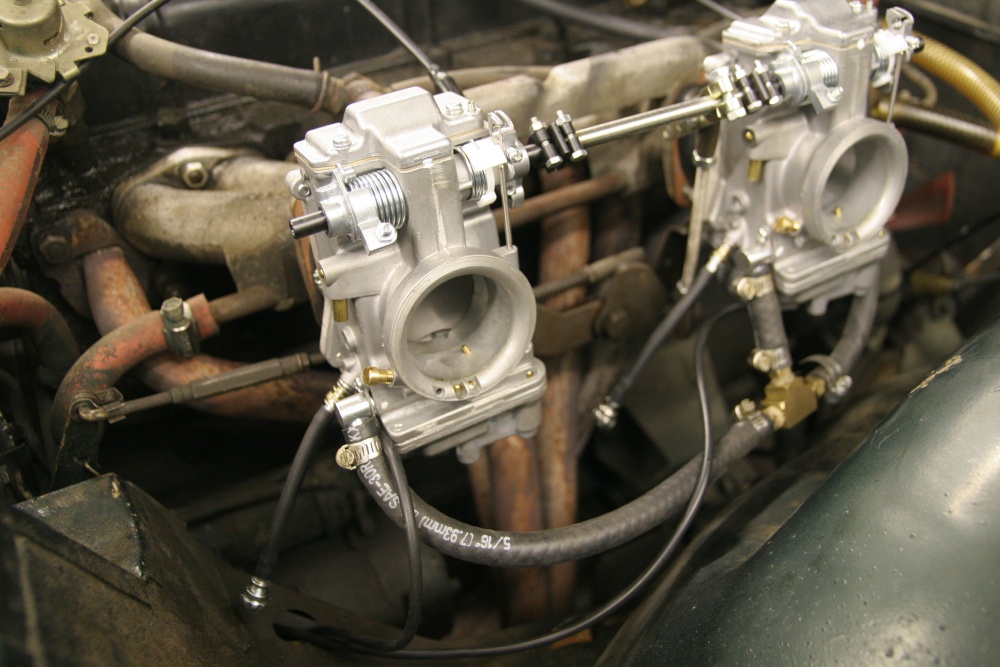

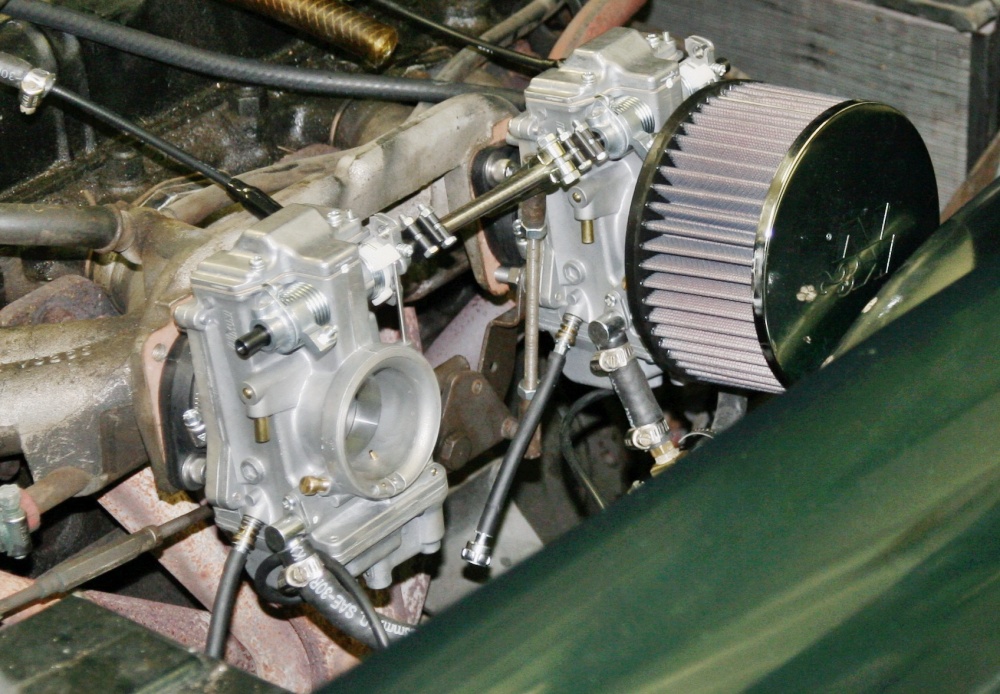

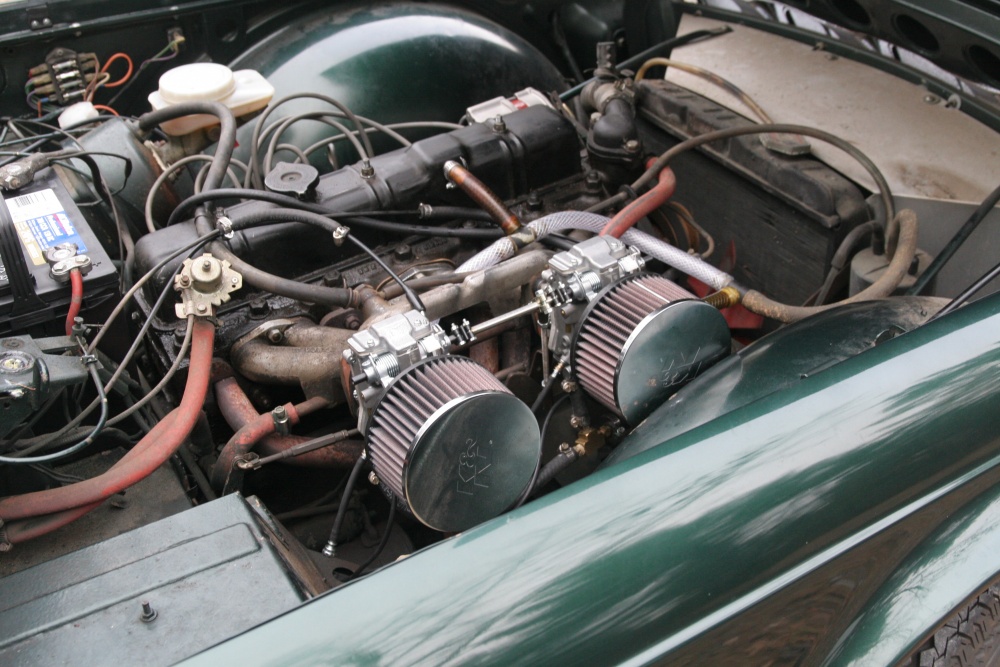

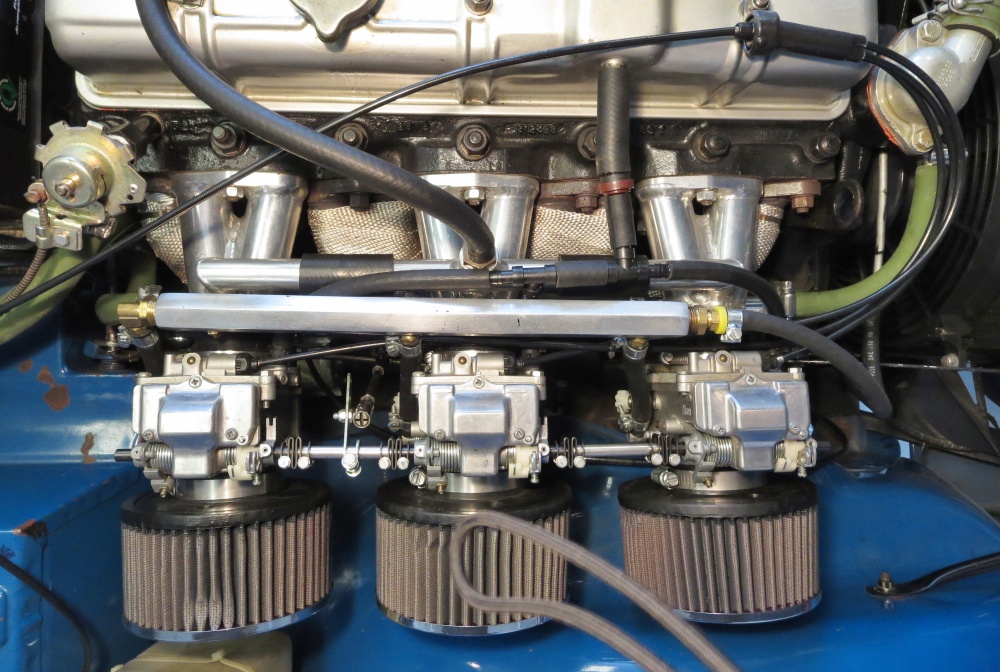

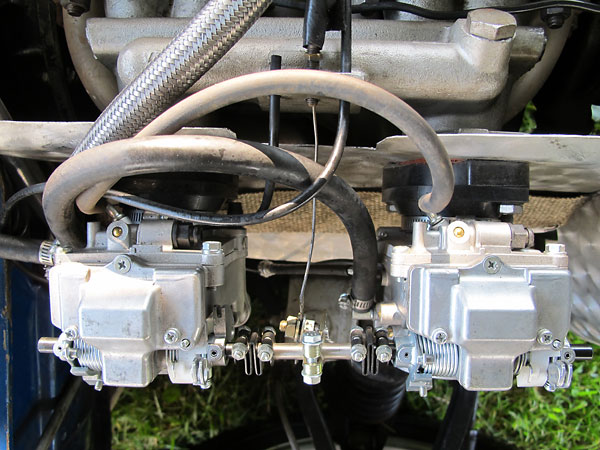

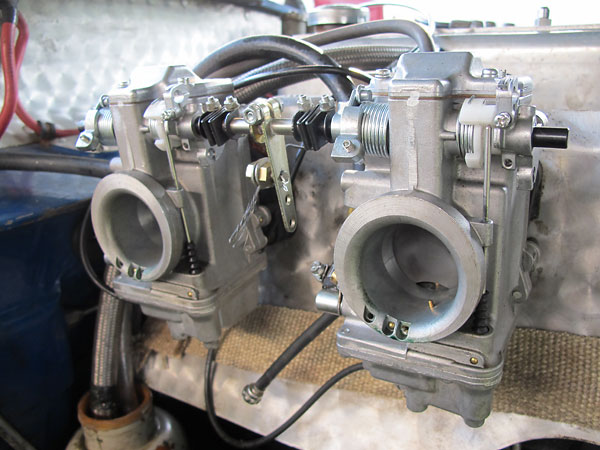

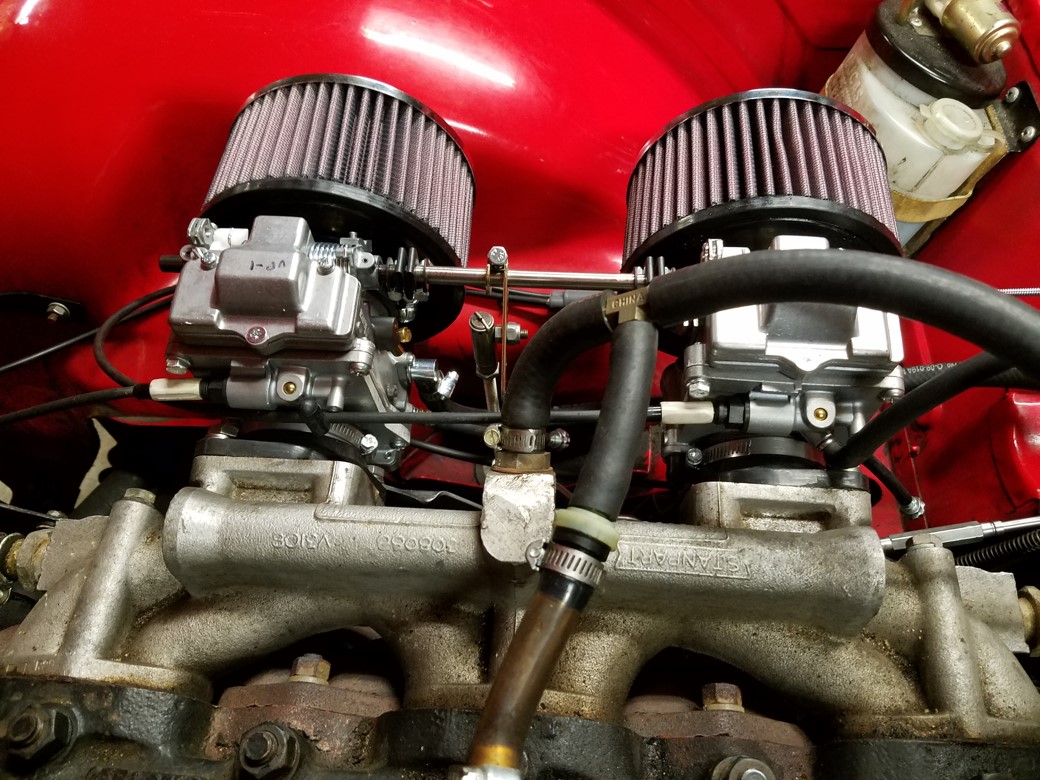

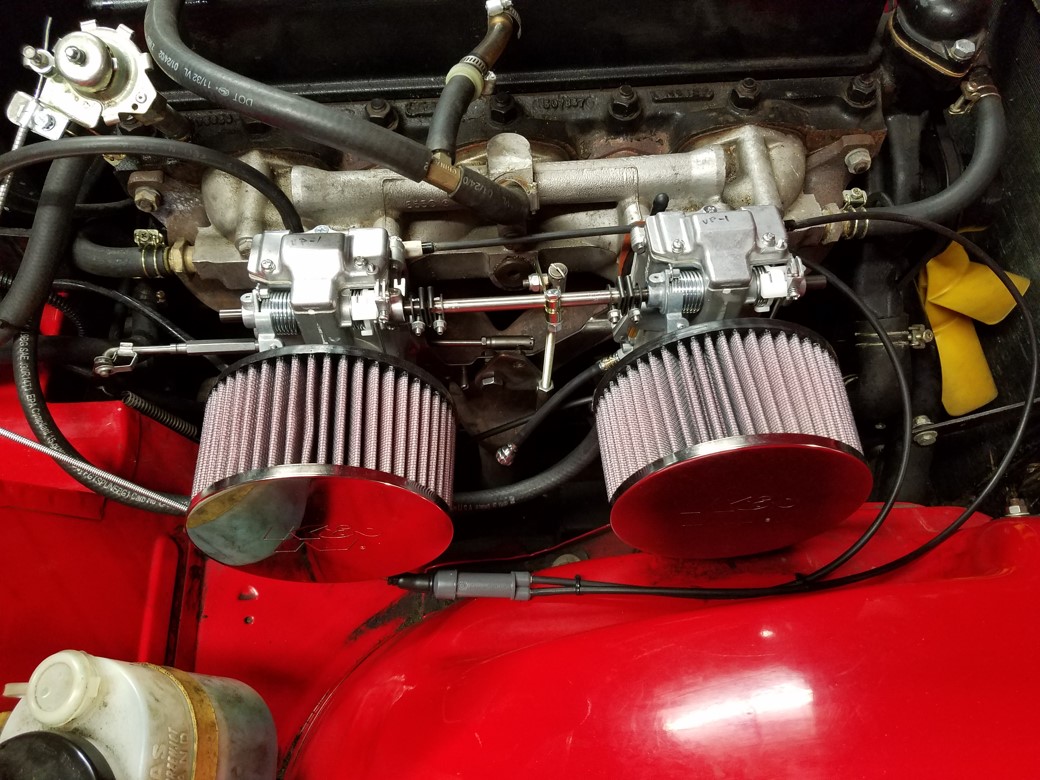

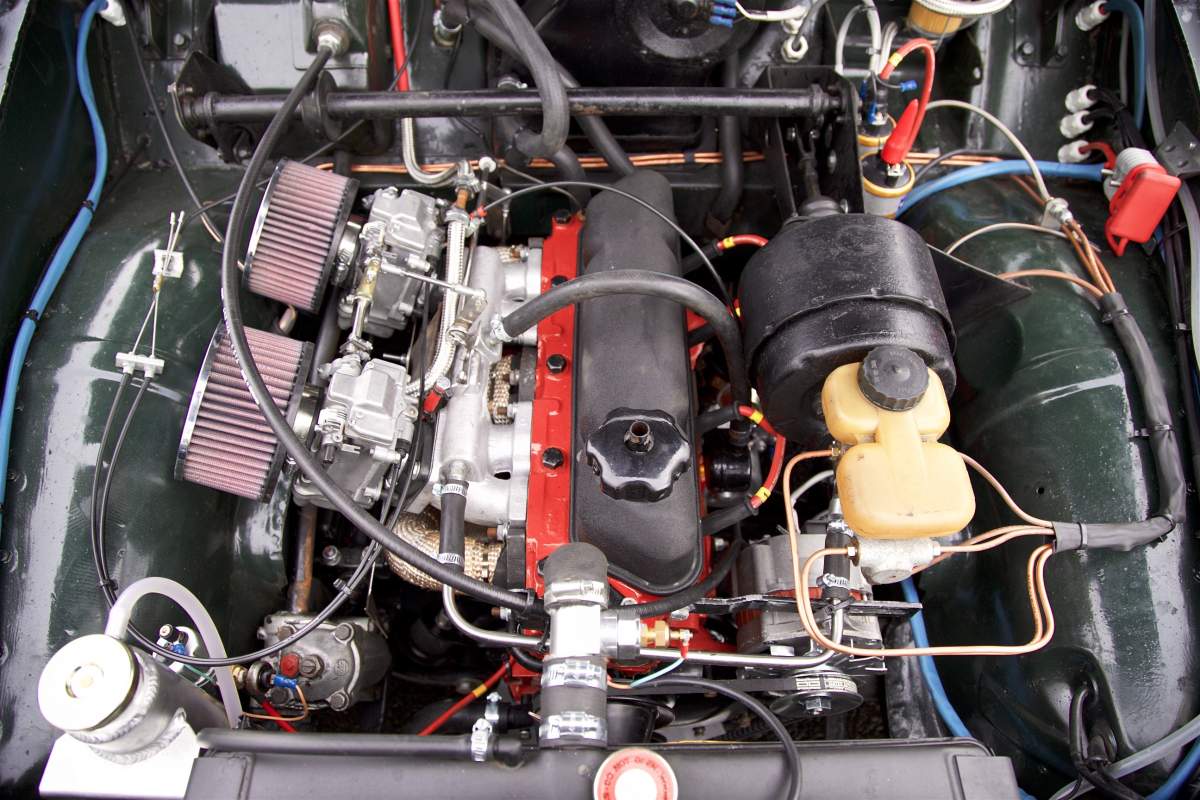

The Supercharger System Kit for Volvo B18/B20 engines comes complete with Autorotor Supercharger, Laminova 3 tube water to air intercooler, Nissens intercooler radiator, new custom modified Mikuni carb for the carbed version, and all other parts needed to make this a bolt on kit. The fuel injected version does not include the programmable fuel injection system which is needed to replace the original D Jet system. Recommended FI systems include Megasquirt and Simple Digital Systems.

Prices for the complete supercharger system are $4195 for the Mikuni carbed version, $3595 for the fuel injection ready version without throttle body, and $3895 for the fuel injected version with throttle body and linkage, including recent upgrades, plus $75 in refundable core charges.

Currently, no further supercharger orders are being accepted for the .87 liter displacement supercharger until more are available from Autorotor/Lysholm. However there is a good supply of the slightly smaller .76 liter compressors and these can also be used in our kits.

Below is the supercharger section from our old website.

In the spring of 2000 I began testing a modern, positive displacement, belt driven supercharger on a 1968 1800. The results were truly astounding and transformed the car's performance. Zero - 60 MPH times were reduced by more than 6 seconds with a stock B18 engine. Since then there have been numerous refinements that have allowed that first prototype to evolve into a bolt on kit available to fellow vintage Volvo owners. In the process we have added a state of the art water to air intercooler as an integral part of the kit. On an otherwise stock B20 in an 1800ES, with modified head and exhaust, the system has been dynoed at over 200 HP at only 8 lbs. boost with 0 - 60 times of under 7 seconds.

|

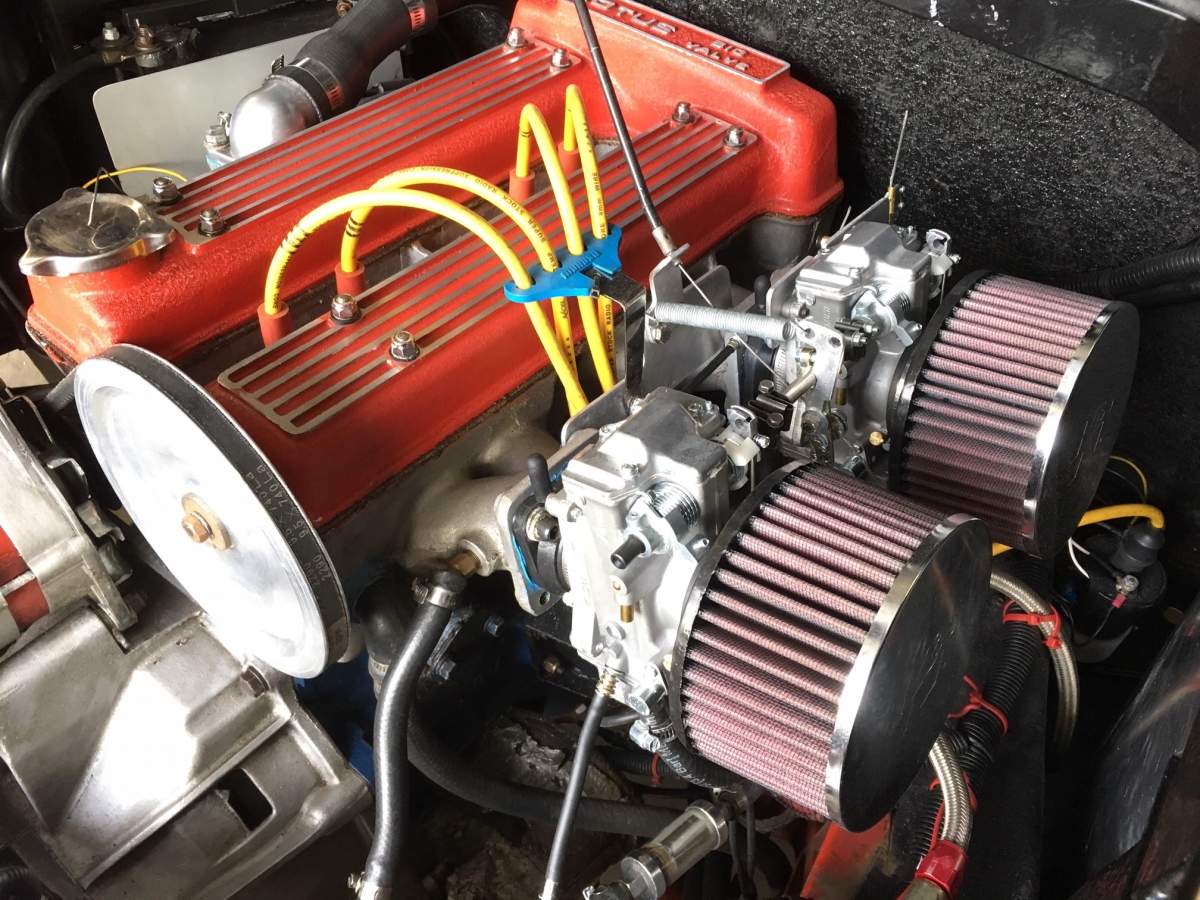

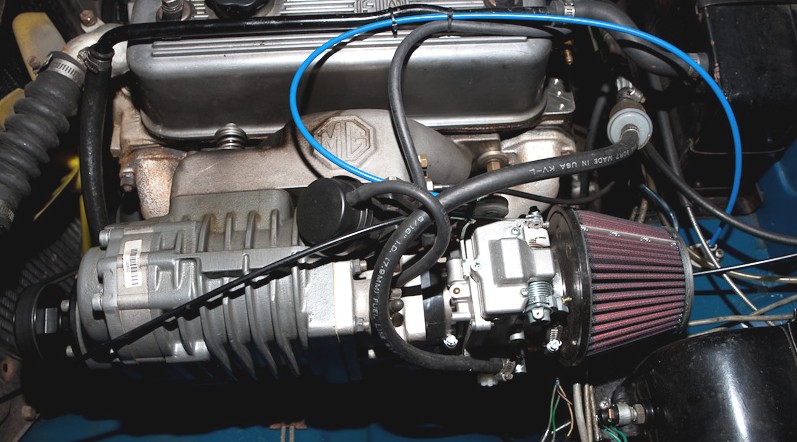

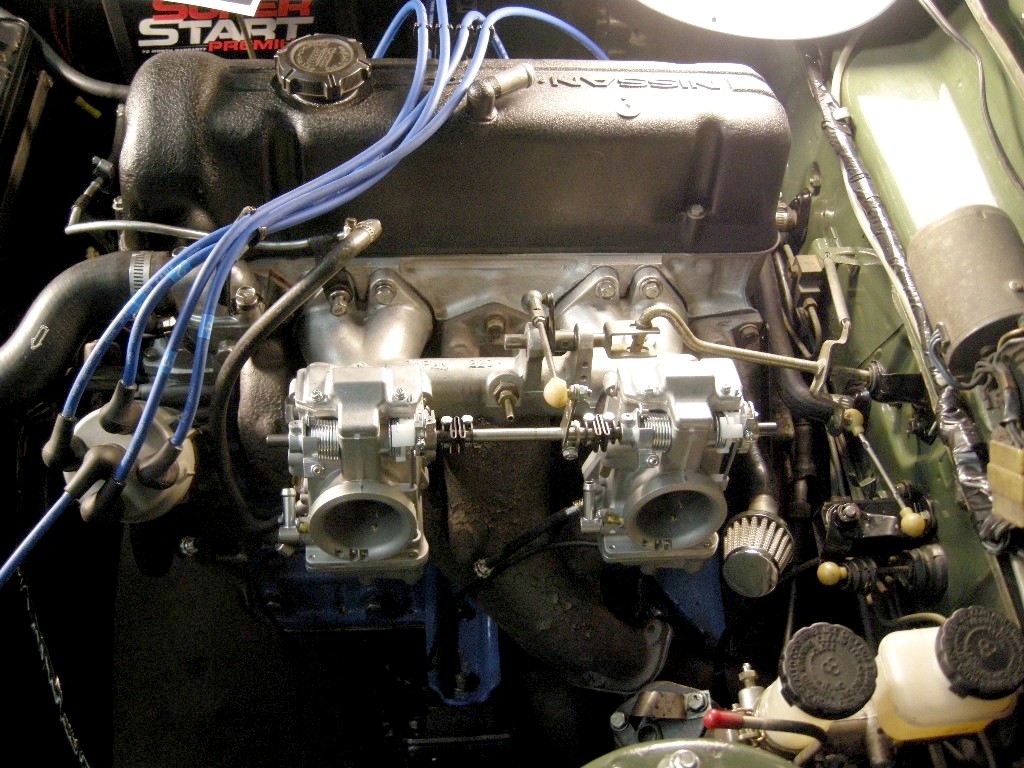

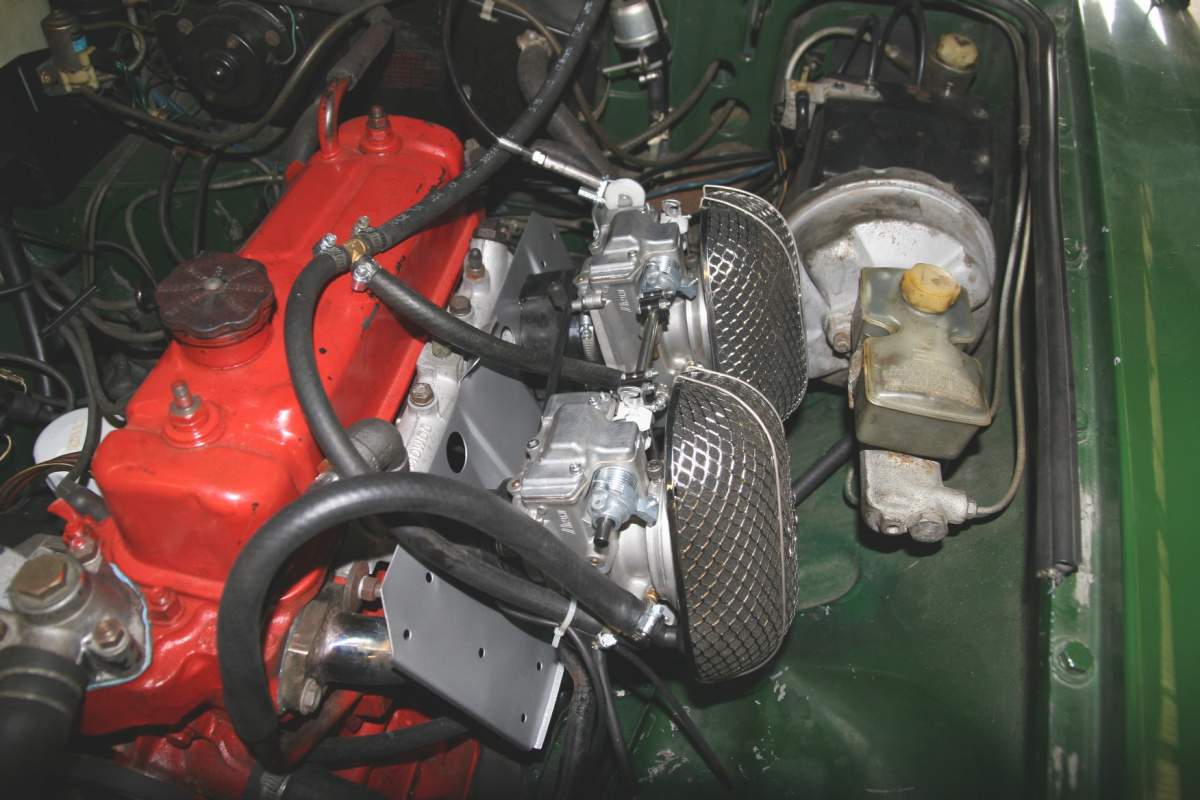

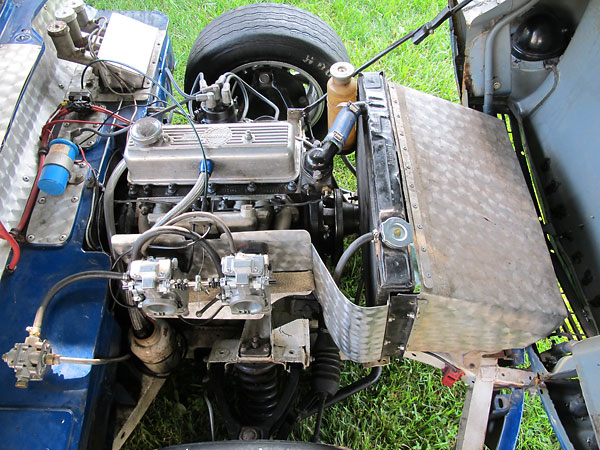

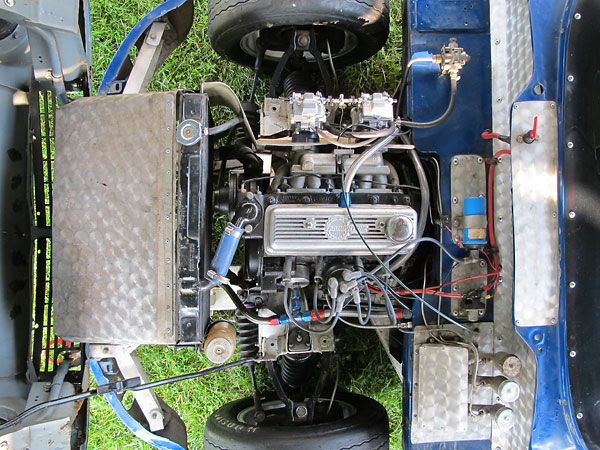

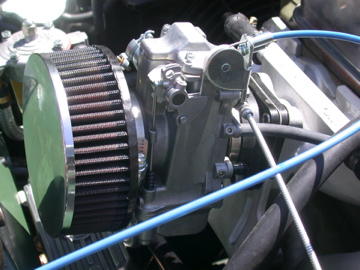

| Supercharger in a 140-series Volvo |

Why a supercharger rather than a turbocharger? There are two basic reasons. First, simplicity - we wanted to make a reliable kit that would be available as a true bolt-on with no engine modifications. Second, driveability - we wanted to produce a system that not only had outstanding performance, but was also easy to drive, with good power throughout the RPM range. Essentially, you don't know that it is supercharged until you put your right foot down.

Our supercharger choice is a belt driven, positive displacement, twin-screw, Lysholm principle supercharger, built by Autorotor in Sweden. Extensive research showed that Lysholm principle superchargers provide several advantages over other designs including greater low rpm boost, higher volumetric efficiency, reduced drive power requirement, and lowered discharge temperatures. These superchargers have the highest thermal efficiency of any fixed displacement superchargers available. But perhaps the greatest benefit of the twin-screw supercharger is its inherent ability to produce consistent, high boost pressures across a wide RPM range.

Although the high efficiency of the supercharger used allows it to function effectively without an intercooler, developments after doing the first prototype made it possible to incorporate a water to air intercooler into the system. As with the supercharger, the Laminova intercooler cores are a patented Swedish design. Using these cores allowed us to create a package that uses one structural unit for both the intake plenum and the intercooler, saving both weight and space, and increasing both horsepower and reliability at minimal additional cost. The system uses a small electric pump to circulate water through the intercooler cores and a front mounted radiator. With the intercooler, supercharger discharge air temperatures are reduced. Lower intake air temps mean a denser charge, less chance of detonation, less engine stress and more POWER!

Are their disadvantages to this design? One disadvantage is cost - you have to pay for high quality. Being the highest quality supercharger/intercooler combination available, the same as used in various Porsche, Mercedes, and BMW aftermarket installations and the same basic design as used in recently introduced high performance AMG Mercedes models, the choice here was to go for quality rather than the lowest possible cost. However, it is another example of getting what you pay for - the best product for your money, and that is consistent with our product philosophy and Volvo's.

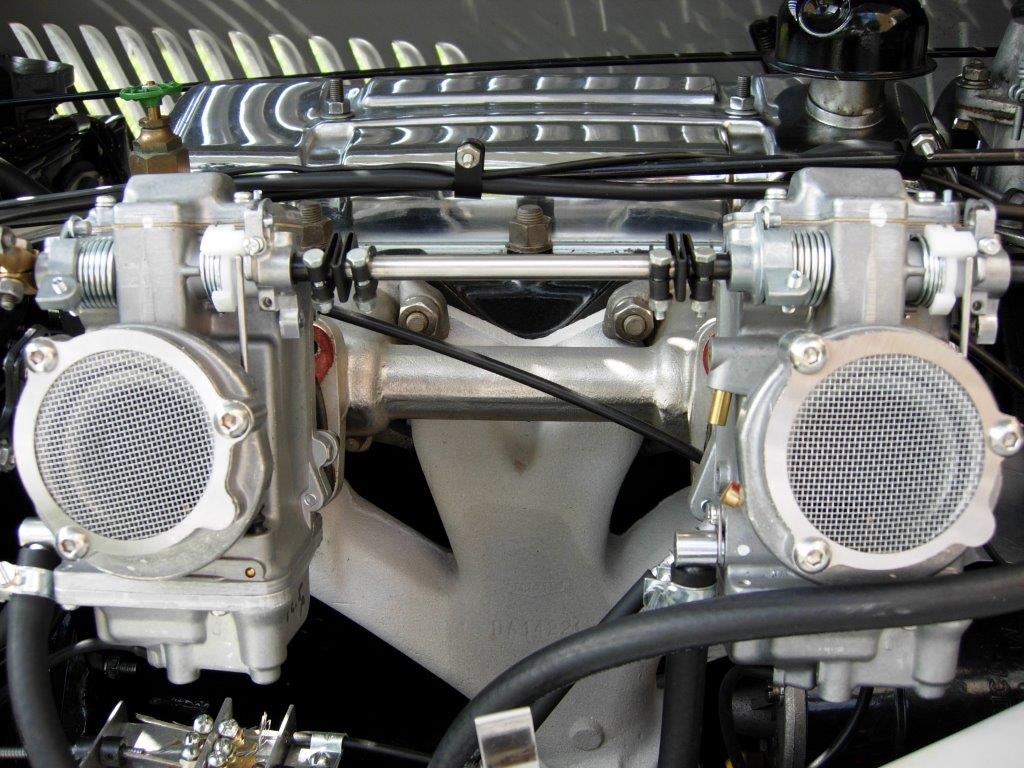

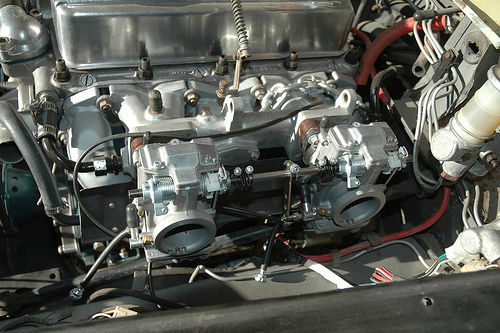

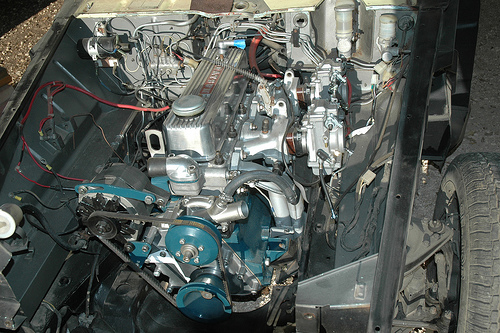

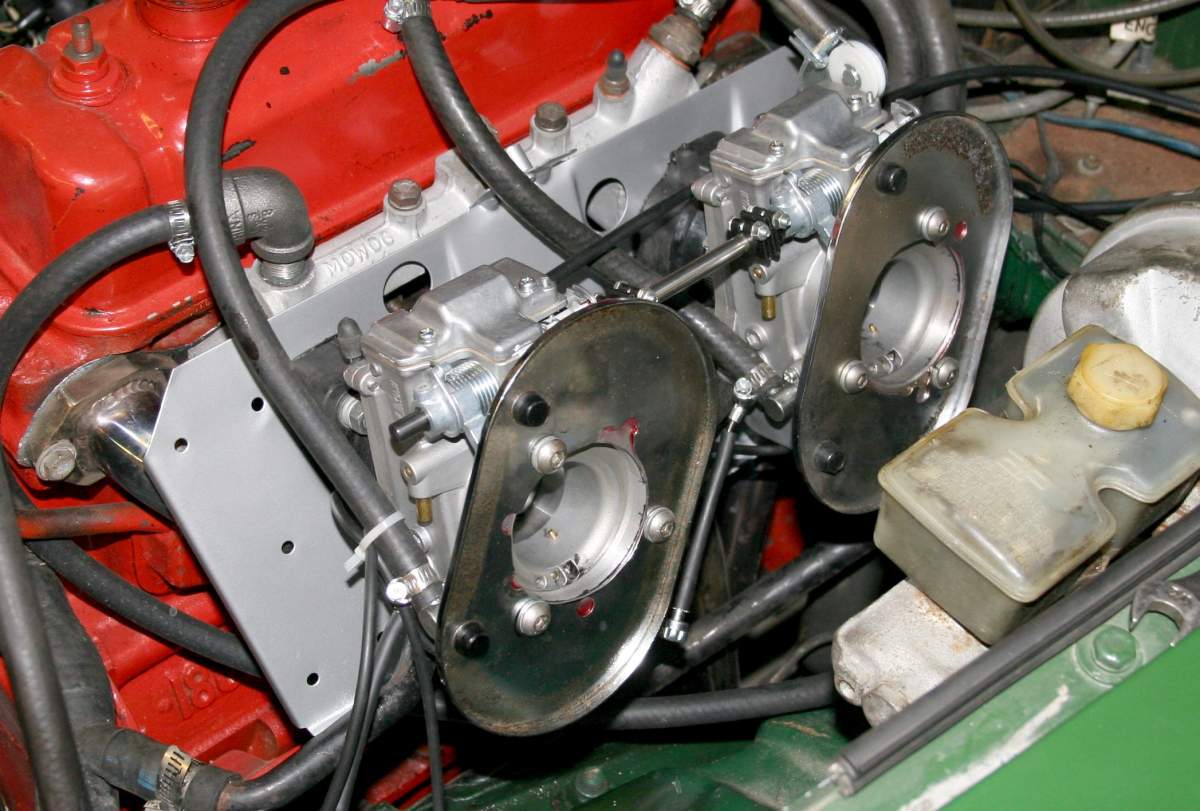

The supercharger-intercooler unit bolts on in place of the stock carburetors or fuel injection manifold.

|

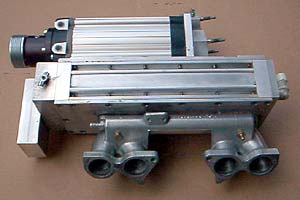

| Supercharger and Intercooler |

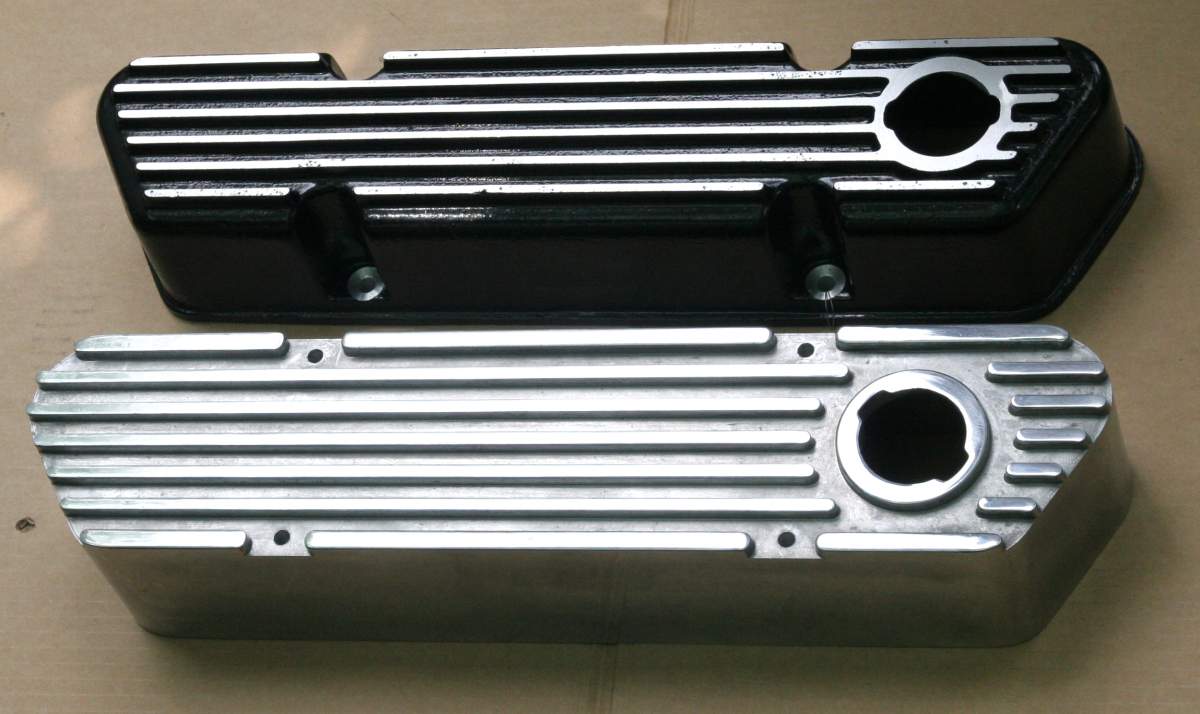

Installation of the whole system requires 4-8 hours depending on skill levels. Installation on fuel injected 1800s and 140s requires a few extra steps, but does not require replacement of the fuel injection fuel pump, lines, filter, etc. If you perform the maintenance on your own vehicle you have the skill required to install this supercharger system, and do it in a day. The system comes complete with a suitably tuned sidedraft Weber 45 DCOE carb, air cleaner, modified crank pulley, belt tensioner, hardware, belts, hoses, connectors and adapters, and is ready to install. Once installed and tuned it is essentially a maintenance free system, other than the routine type of inspection needed for any automotive accessory drive belt drive.

The initial kits have been designed for all B18 and B20 engines, whether carbed or fuel injected, but without air conditioning. A second version, available soon, with a modified belt drive system will accommodate air conditioned vehicles. Work on a system that will allow the use of an aftermarket fuel injection system is underway. Continued development and testing will produce additional modifications designed to incrementally increase all aspects of the car's performance.

Reservations should be made in advance as kits are done on a custom basis and take approximately 12 - 14 weeks from the date of order to delivery. Costs have gone up due largely to the lower value of the dollar. The current price is $4195 for the new Mikuni carbed version, $3595 for the fuel injection ready version without throttle body, and $3895 for the fuel injected version with throttle body and linkage, including recent upgrades, plus $75 in refundable core charges. The kit comes complete with Autorotor Supercharger, Laminova 3 tube water to air intercooler, Nissens intercooler radiator, new custom modified Mikuni carb for the carbed version, and all other parts needed to make this a bolt on kit. The fuel injected version does not include a programmable fuel injection system which is needed to replace the original D Jet system.

Currently, no further supercharger orders are being accepted for the .87 liter displacement supercharger until more are available from Autorotor/Lysholm. However there is a good supply of the slightly smaller .76 liter compressors and these can also be used in our kits.

The Supercharger

Our system uses an Autorotor supercharger of unsurpassed quality, designed and built in Sweden. It is a positive displacement, twin rotor, Lyshom principle supercharger of approximately one liter displacement. The Lysholm principle provides several key advantages over all other types of superchargers: greater low rpm boost, higher volumetric efficiency, reduced drive power requirement, and lower discharge temperatures. This supercharger has the highest thermal efficiency of any fixed displacement supercharger in production in the world today. This efficiency is reflected in an intake temperature rise, before the intercooler, of less than 90 degrees F at full boost and is a key to significantly increasing engine power without over stressing the engine.

From the driver's point of view, the chief advantage of this supercharger is its inherent ability to produce consistent boost pressures across its operating range, starting at extremely low engine RPMs. There is no feeling of "coming on the cam," or "turbo lag," only prodigious low end torque that continues as the car accelerates. In tests, full boost has been achieved as low as 1500 RPM. The resulting flexibility in engine operation is clearly unmatched by any other performance system.

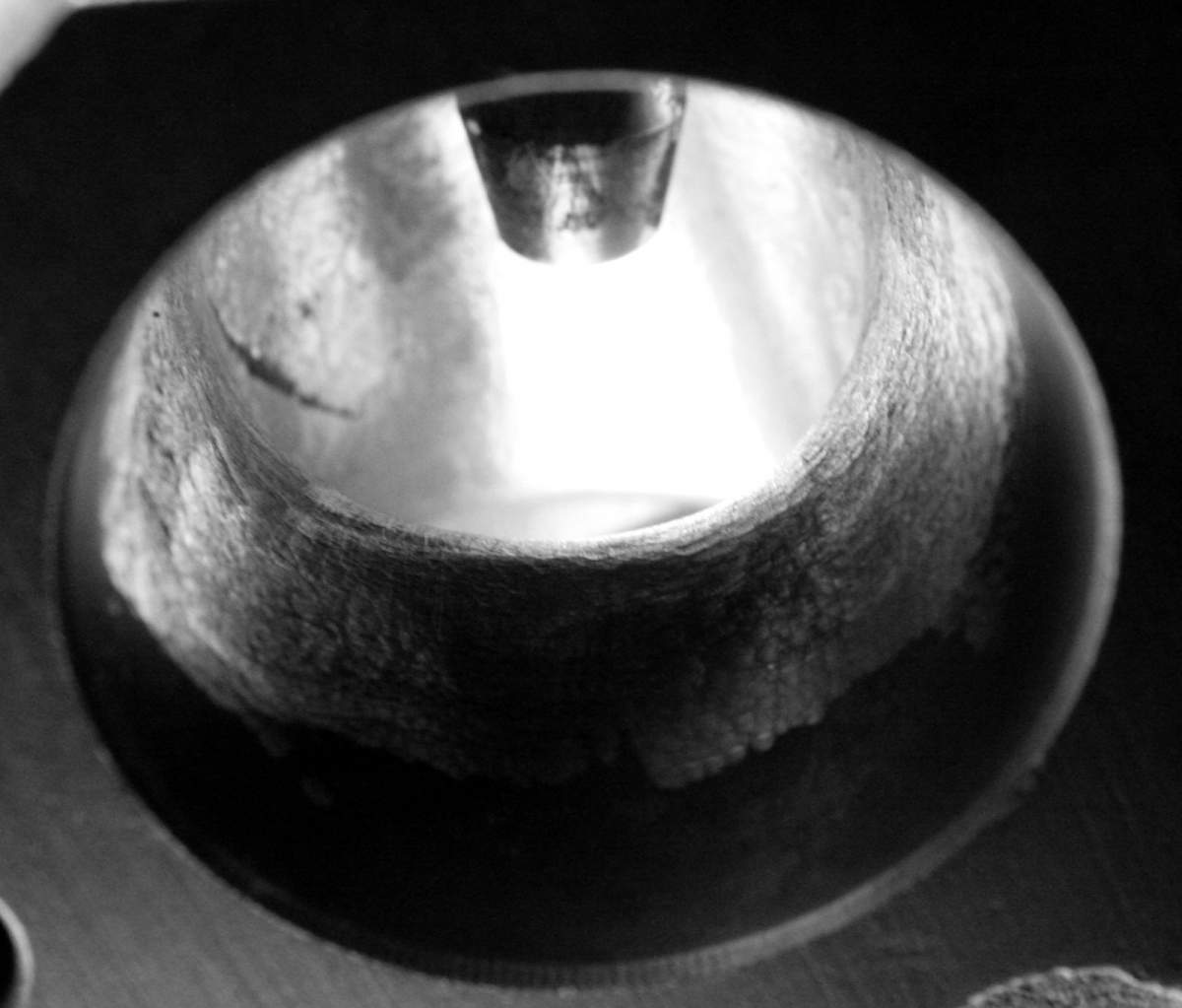

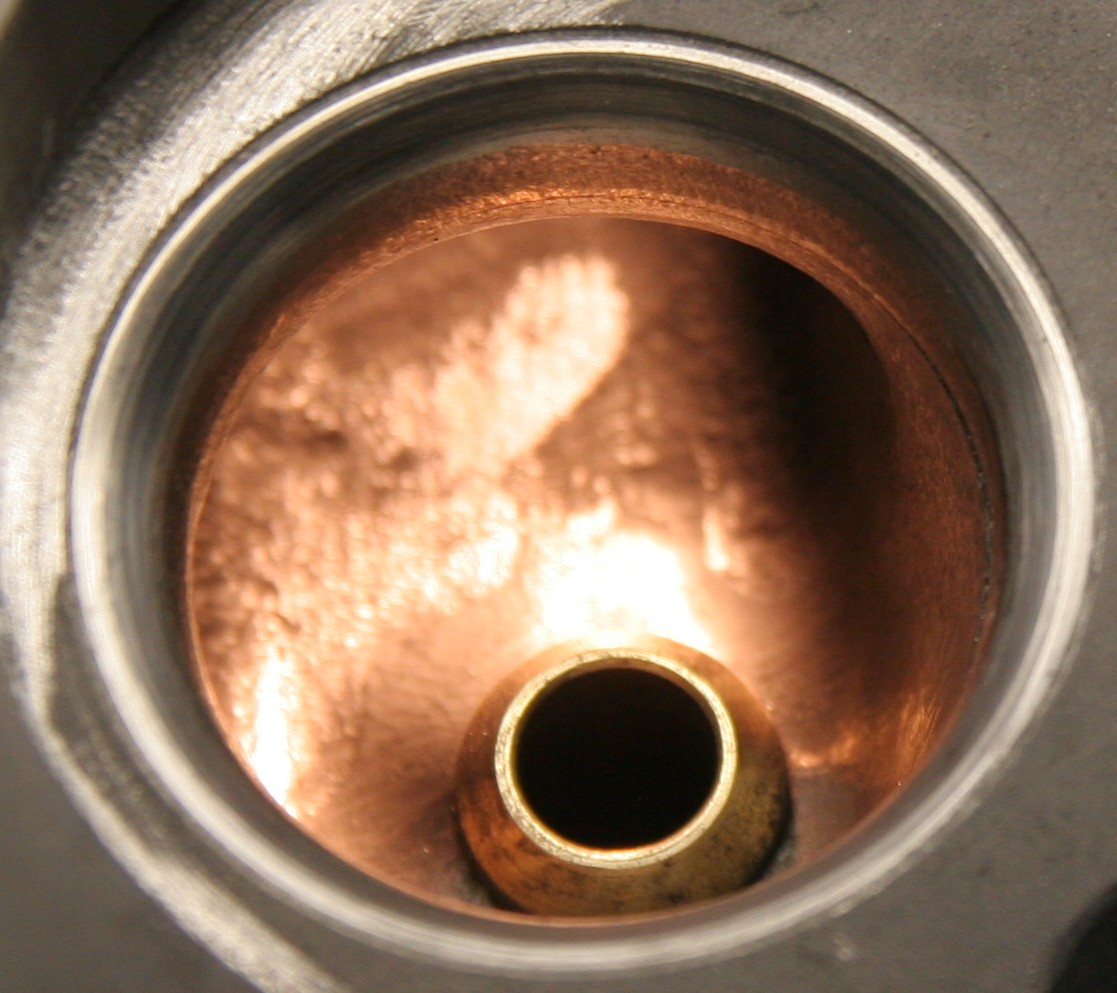

A supercharger is basically an air compressor. The basic features of this type of compressor are two helical, gear driven shafts, one with concave lobes, the other with convex cavities which intermesh at high speed, thereby compressing the air.  It is a positive displacement pump but has no contacting parts to wear out as in the old vane type superchargers. The air is drawn in at one end of the case, compressed between the rotors and expelled from the other end of the case in a fixed ratio. These superchargers have been used in demanding industrial applications for years where extreme reliability and low maintenance were primary requirements. Only recently have advances in manufacturing techniques allowed their cost to be reduced to the level that they can be economically produced for automotive applications where they are considered to be the highest quality supercharger available.

It is a positive displacement pump but has no contacting parts to wear out as in the old vane type superchargers. The air is drawn in at one end of the case, compressed between the rotors and expelled from the other end of the case in a fixed ratio. These superchargers have been used in demanding industrial applications for years where extreme reliability and low maintenance were primary requirements. Only recently have advances in manufacturing techniques allowed their cost to be reduced to the level that they can be economically produced for automotive applications where they are considered to be the highest quality supercharger available.

The supercharger itself is essentially a sealed, self lubricating unit, with an industrial use rating of 22,000 hours at 15,000 RPM. That translates into more than 1 million miles at 60 MPH before a rebuild would be required. The gears which drive the twin screws do require lubrication. In order to eliminate the need for maintenance, or checking oil levels as in some other kits, our system lubricates the gears using engine oil fed by the engine's own lubrication system. All oil lines and fittings for the lubrication system are included.

With an appropriately sized supercharger in relation to engine displacement, boost levels are determined largely by the speed ratio between the supercharger and the engine. As it is a positive displacement supercharger, this is a linear ratio. A 50% increase in the RPM of the supercharger in relation to engine speed will produce a theoretical 50% increase in boost pressure, all other things being equal. See the "drive system" section for more information on changing boost levels.

The Next Generation of the Supercharger System

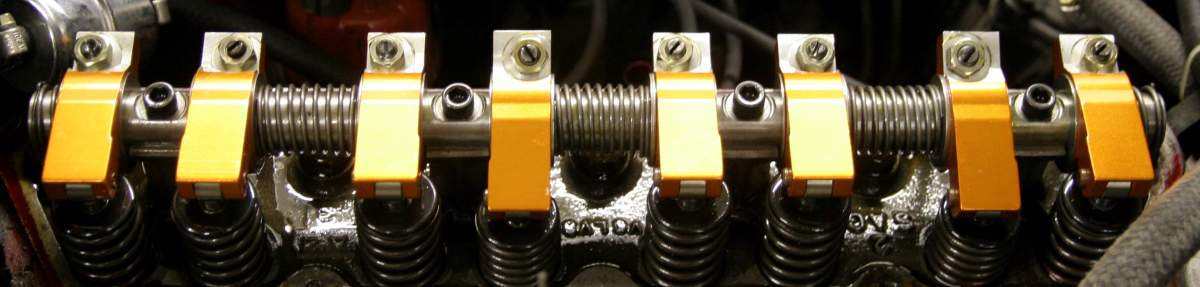

It has now been 7 years since our first supercharger system hit the road. Followed by the intercooled version a year later, it revolutionized the concept of the power that could be obtained from a B18/B20 pushrod motor and the kind of performance that you could enjoy in a vintage Volvo. Since then, changes have been more evolutionary in nature.

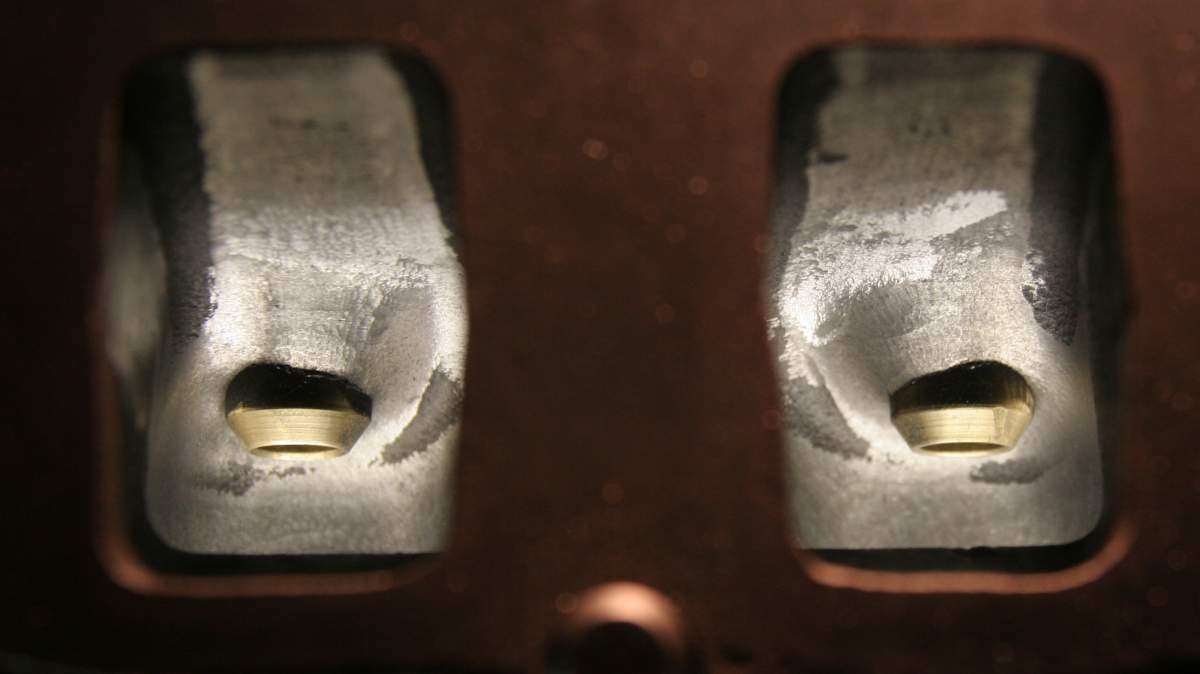

Development of the system continues and now allows us to produce more power per pound of boost with improved fuel economy. Improvements in cam, head and exhaust design have been essential to this process. One result has been a cam designed specifically for use with the SC system. For 200 HP or more, one of our Street Performance Heads is a necessary element. Customers using other ported heads have not been able to achieve the same power.

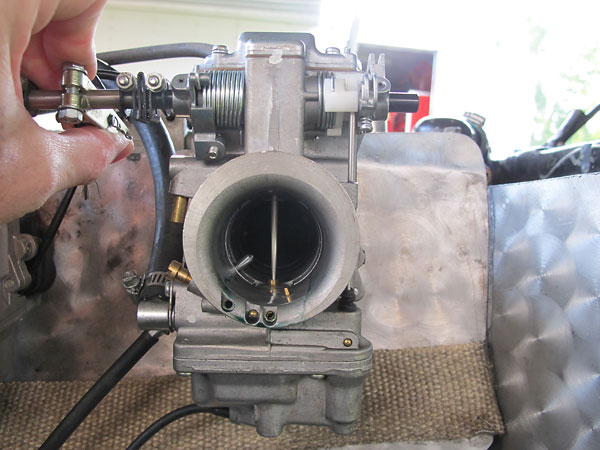

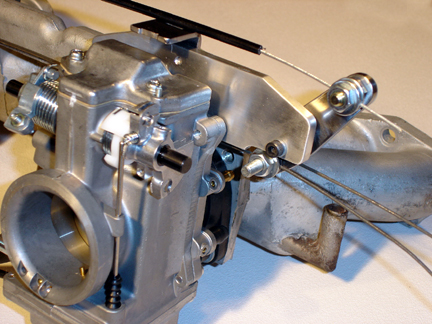

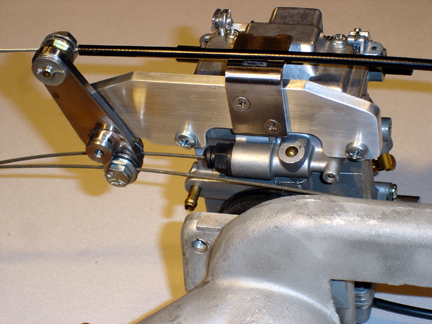

In the beginning, producing power was almost the only consideration. But having met our original performance goals, the goals for the system have broadened, with improvements in long term reliability and fuel mileage becoming more important than power increases. To implement these improvements, changes to the system include CNC machined aluminum crank pulleys, a spring loaded belt tensioner system for the drive belt, new anodized aluminum idler pulleys of our own design, and an intercooler radiator 40% larger than the original. But the most significant change to date is in the carburetor. We now use a modified version of the same HSR 45 Mikuni described above as an "SU replacement," and use it to get an increase of more than 50% in cruising fuel mileage. With this carb you no longer have to sacrifice fuel mileage when you opt for supercharger performance - cruising at 25 mpg is routine.

To implement these improvements, changes to the system include CNC machined aluminum crank pulleys, a spring loaded belt tensioner system for the drive belt, new anodized aluminum idler pulleys of our own design, and an intercooler radiator 40% larger than the original. But the most significant change to date is in the carburetor. We now use a modified version of the same HSR 45 Mikuni described above as an "SU replacement," and use it to get an increase of more than 50% in cruising fuel mileage. With this carb you no longer have to sacrifice fuel mileage when you opt for supercharger performance - cruising at 25 mpg is routine.

With normally aspirated B20s available with power in the 150 - 200 HP range, our basic recommendation is to reserve supercharging for those customers who want at least 180 HP. We also recommend that all supercharged cars have suspension upgrades and other modifications that are necessary to safely accommodate power levels that will completely transform your car's performance.

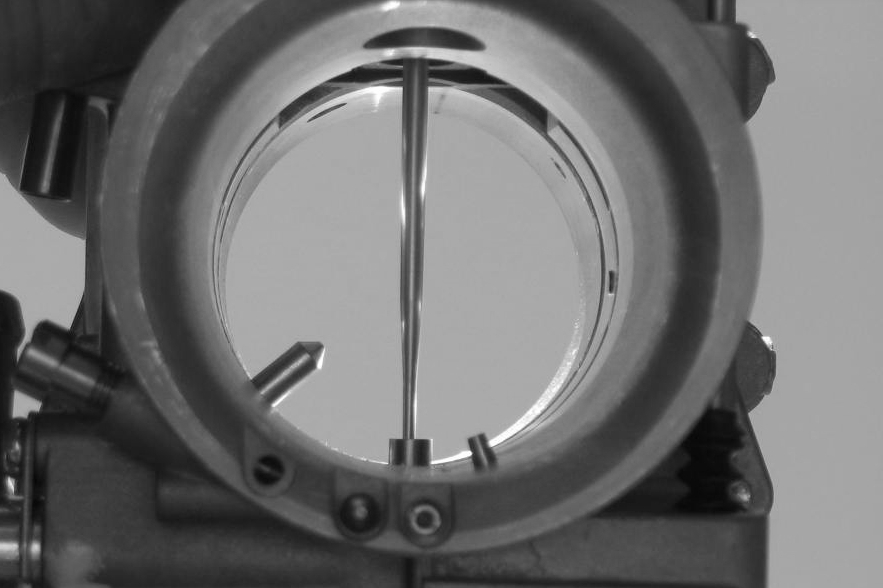

For those who want to use fuel injection, and it is recommended for anyone with a car that currently has FI, we offer a "fuel injection ready" version of the supercharger system. No, it does not include a fuel injection control system. And, no, you can't use it with D-Jet. But you can use it with your stock injectors, fuel rail, fuel pump, fuel lines and fuel pressure regulator. Since we now offer the fuel injected version with an adapter plate, Mustang throttle body with TPS, and throttle linkage, you can now install Megasquirt or Simple Digital Systems, etc, instead of the D-Jet ECU, sensors and wiring, and you are ready to go with a fuel injected supercharger system. See Steve Berry's website www.1800philes.com and an article he wrote that appeared in the Nov. 2006 issue of Grassroots Motorsports magazine for details on using Megasquirt with our supercharger system. Steve also has an S60R, and says his supercharged 1800, even at midrange boost settings, is faster.

For those who want to use fuel injection, and it is recommended for anyone with a car that currently has FI, we offer a "fuel injection ready" version of the supercharger system. No, it does not include a fuel injection control system. And, no, you can't use it with D-Jet. But you can use it with your stock injectors, fuel rail, fuel pump, fuel lines and fuel pressure regulator. Since we now offer the fuel injected version with an adapter plate, Mustang throttle body with TPS, and throttle linkage, you can now install Megasquirt or Simple Digital Systems, etc, instead of the D-Jet ECU, sensors and wiring, and you are ready to go with a fuel injected supercharger system. See Steve Berry's website www.1800philes.com and an article he wrote that appeared in the Nov. 2006 issue of Grassroots Motorsports magazine for details on using Megasquirt with our supercharger system. Steve also has an S60R, and says his supercharged 1800, even at midrange boost settings, is faster.

And for those of you who insist on ruining the traditional sports car experience of being either too hot or too cold by insisting on air conditioning, for 2006 we will have a kit that will allow the supercharger system to be used with AC.

Our original power goal with an otherwise perfectly stock engine was 150 HP. The next goal, with a modified head and exhaust system, was 200 HP at 8 lbs. boost, then 250 HP at 15 lbs. All were achieved. Then the priorities became refinement, reliability, and fuel mileage. Now, having met our goals in those areas we can turn back to power. So for 2007 our power goal will be double the original: 300 HP from a 2 liter street engine, 3 times stock HP, while still getting 25 - 30 miles per gallon. Check back for details.

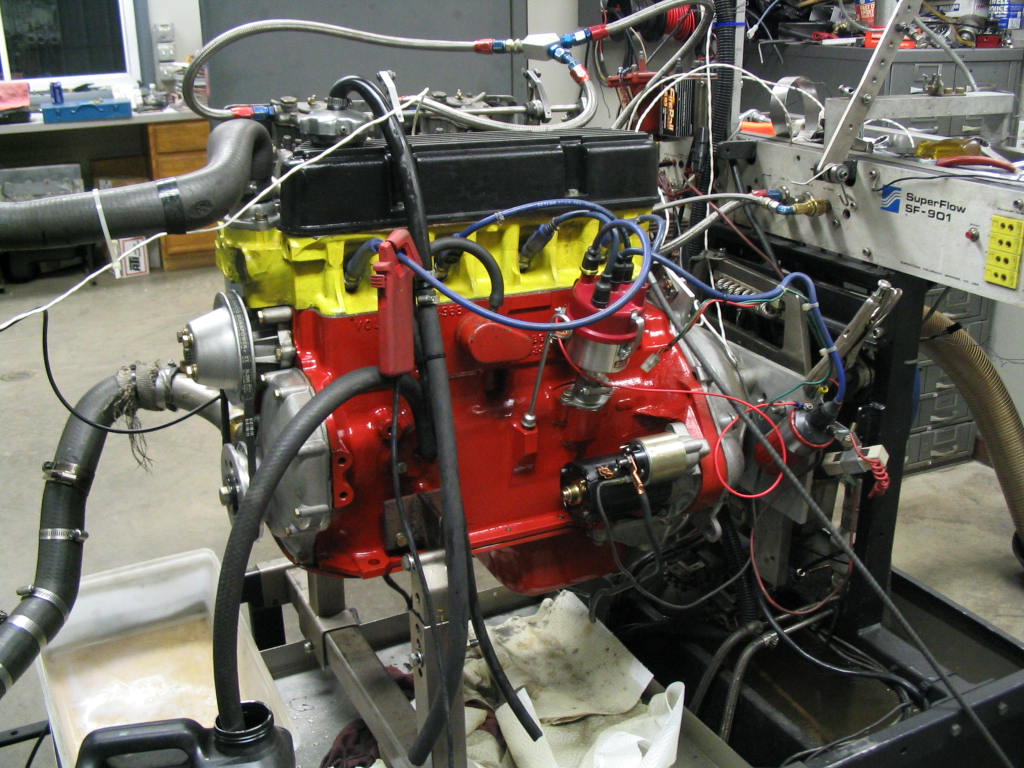

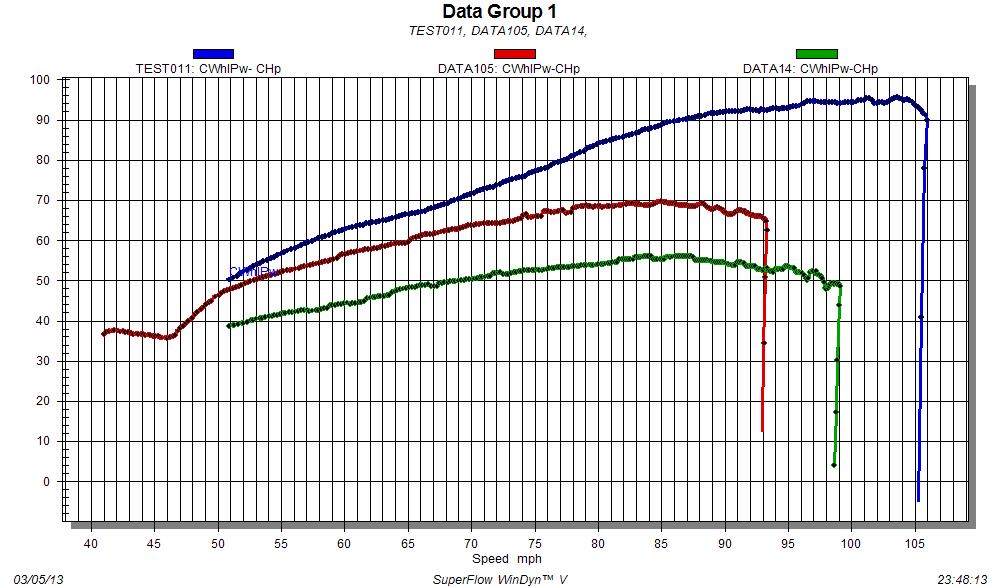

The dyno chart below shows the power progression from stock engine to the most popular configuration - 10 lbs. of boost producing 216 HP at the flywheel and 221 ft. lbs. of torque.

The dyno chart compares tests of flywheel horsepower of a stock 1800ES with three different supercharged configurations. The bottom line is the stock ES. The 2nd line from the bottom represents the same car with stock engine and exhaust system with the supercharger producing a maximum of 7.7 lbs. boost. The 3rd line from the bottom is the same stock engine and exhaust with a different SC drive pulley ratio producing up to 10.5 lbs. boost. The top line is the same car with our performance head, "C" cam, 4-2-1 header, and 2-1/2 inch exhaust system with muffler and resonator at 10 lbs boost, clearly demonstrating that you do not need to increase boost to increase power. This power level in an 1800 is good for 0-60 times in the 5 second range.

Intercooler System

Compressing a gas increases its temperature. The purpose of an intercooler is to reduce the temperature of the air compressed by the supercharger. As the result of the reduction of temperature a denser charge is produced. A denser,

|

| The Intercooler |

Our intercooler is of the water to air type. Like the supercharger it is a patented design, using heat exchanger cores made by Laminova in Sweden. Unlike the typical intercooler that uses air to air cooling, it uses water ( or a water/antifreeze mix ) to cool the air compressed by the supercharger. The higher specific heat value of water gives this type of system a distinct advantage in its ability to absorb heat energy, and also allows for a much more compact installation.

The system essentially consists of two small heat exchanger units. One is a radiator, mounted in front of the vehicle's normal radiator. There water is cooled by outside air moving through the radiator in the same manner as in the vehicle's cooling system.

|

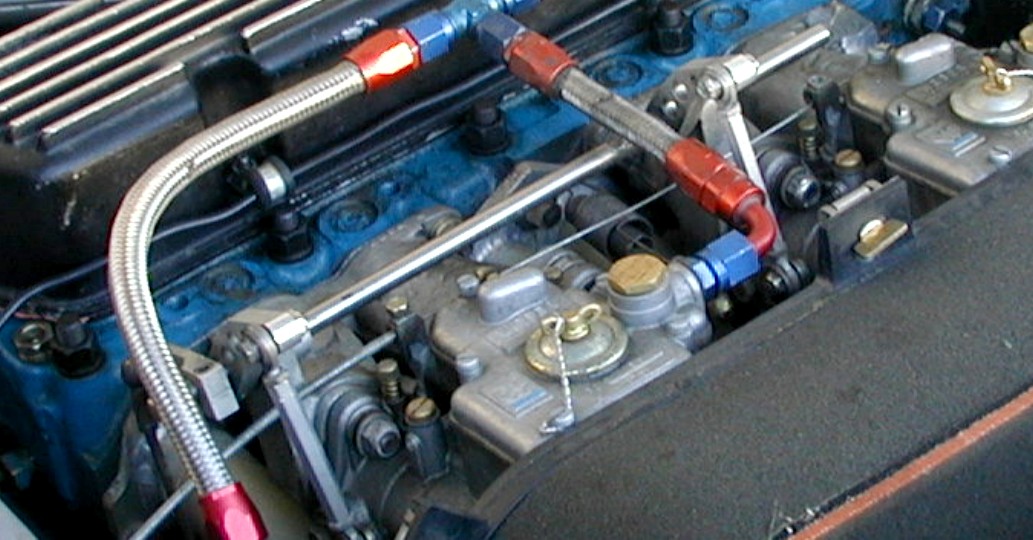

| Intercooler radiator, coolant pump and filler tank |

Brackets, hoses, an electrically powered water pump (also made in Sweden), and an aluminum expansion tank are all included in the kit and are easily installed. The pump is designed to be in operation whenever the engine is on; thus no complicated wiring is necessary.

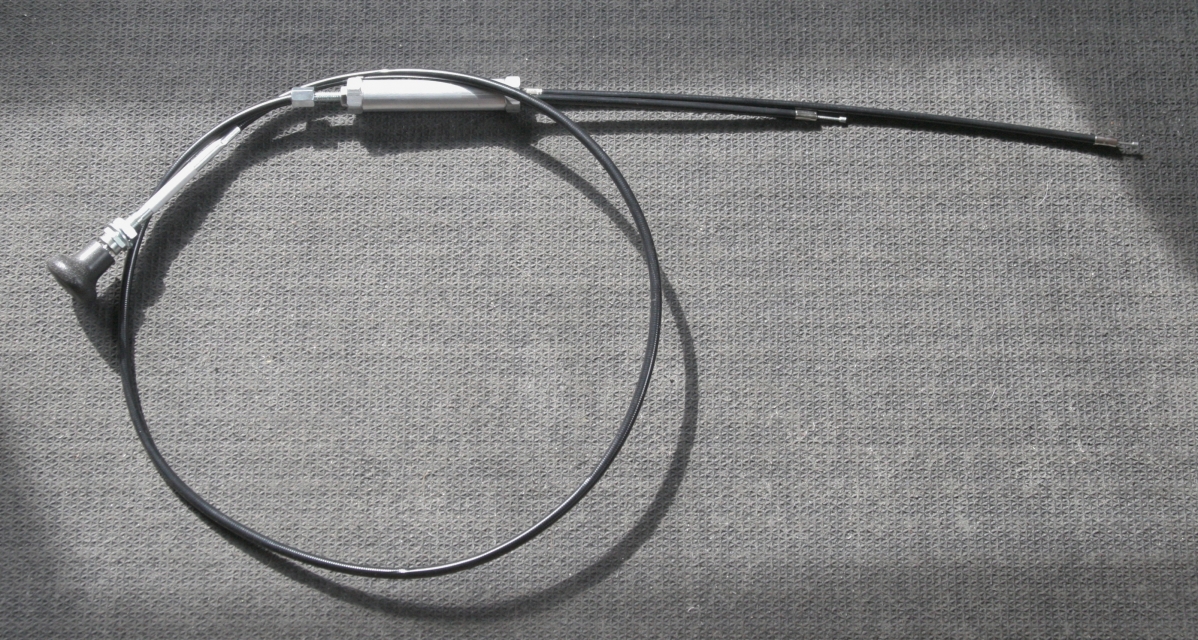

Drive System

The supercharger is driven by a modern, multi-rib drive belt system running off of the engine's crankshaft. The crankshaft pulley has been modified to accept this belt in addition to the normal fan/alternator belt. A high quality idler pulley is part of the system. Not only does this provide for positive location of the belt, but it is also used to provide the necessary tension for the belt system.

|

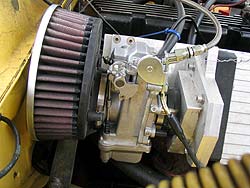

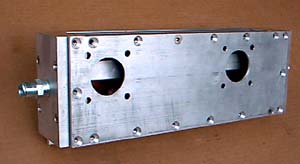

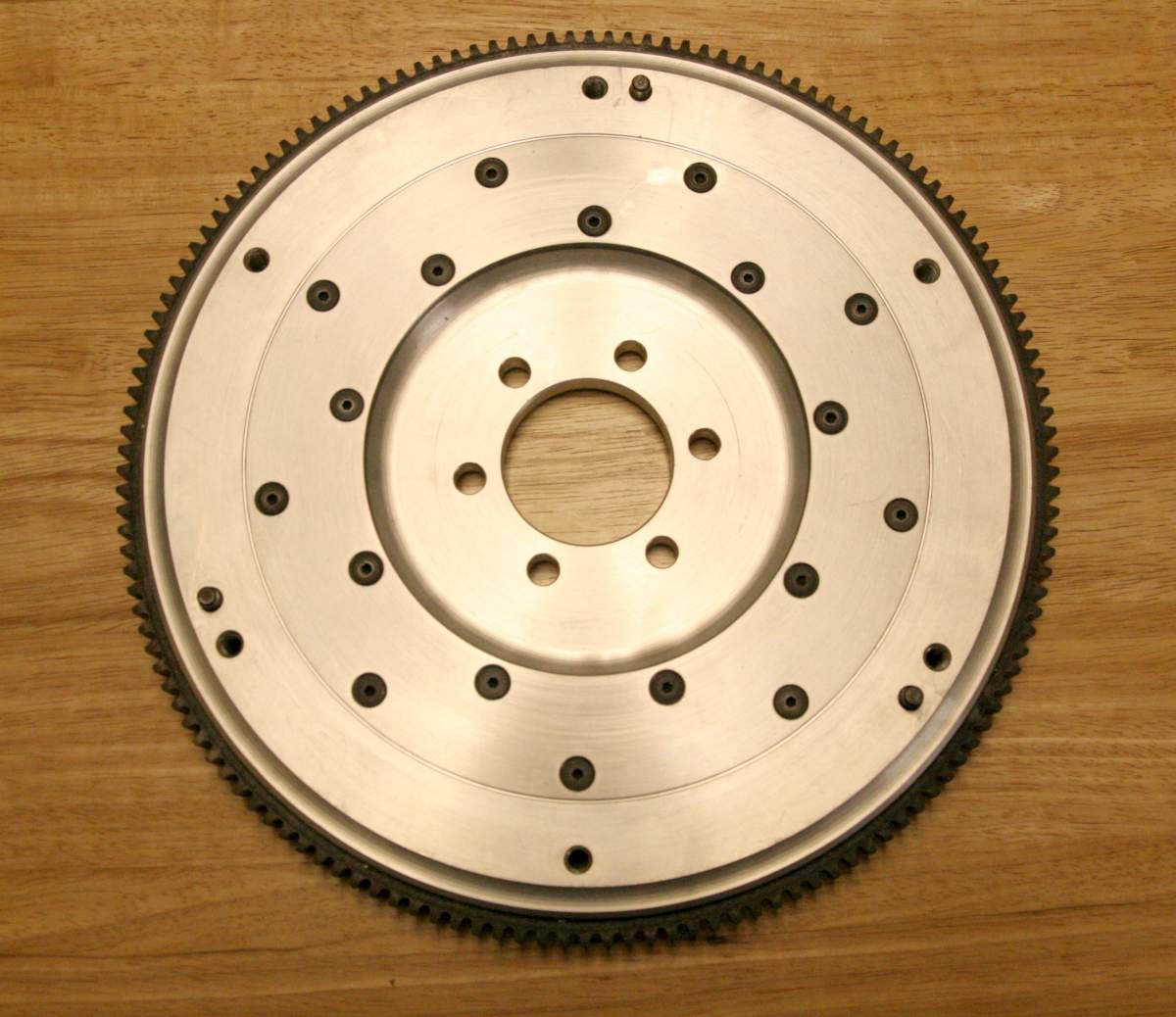

| Aluminum crank pulley for the supercharger drive belt |

One of the advantages of this type of drive system is the ease at which boost levels can be changed or adjusted. The boost level of the system is based on the speed ratio between the engine and the compressor. The compressor pulley can be replaced with larger or smaller pulleys in order to vary this ratio and therefore the boost level. This change can be accomplished in a few minutes and requires only that the supercharger pulley and the drive belt be removed and replaced by different size units. This allows the user to change the boost level to accommodate various circumstances such as the use of higher or lower octane fuel, or the need for more power for a weekend autocross or track day.

Performance Testing

Performance testing of the system began in the spring of 2000 with the prototype unit. The test car was a 1968 1800, with completely stock B18 engine and exhaust system. Preliminary tests before installation resulted in 0 - 60 times of 13.5 seconds, essentially the same as the results obtained when the car was new according to contemporary road tests. With the supercharger producing 10 lbs. boost we got consistent 0 - 60 times of 7.5 seconds. After a summer of testing, tuning and minor modifications, further testing was cut short when the parked test car was hit by a drunk driver at 5 AM one Saturday morning. The engine was pulled, opened up and examined. It showed no signs of any problems, even though we had run it with as much as 15 lbs. boost. Although we did not get to complete chassis dyno tests that had been scheduled, we felt we had enough information and test mileage to proceed with the design of a production version.

The process of going from prototype to production resulted in several design changes, and the final product is clearly improved, both from a customer value standpoint and improved performance. The inclusion of an integrated intercooler system was the most significant of these changes, but was only one of a number of refinements.

The delays apparently typical of the introduction of any new product put us behind schedule in going from prototype to a production version of the intercooled system. Rather than test another prototype we delayed further testing until we could test with true production parts. It took until the fall of 2001 before we were ready.

As there was significant interest in adapting the supercharger to injected cars and we wanted to be able to test through a salty northeast winter, I decided to use a recently purchased unrestored 1800ES as the test car. ("I'll sell it to the first person who can pay $750 cash and pick it up before the end of the week" was roughly the way the e-mailed offer read.) The idea was to test the system on a car that is representative of most of those out there, not a "special" with an engine built for this purpose. At times I regretted this choice, as problems not having anything to do with the supercharger system kept cropping up, and more time was spent restoring various parts of the car just to keep it running than were spent on the supercharger system itself.

Installation on the ES was very straightforward, and there was no problem at all simply hooking the Weber carb to the injected fuel system with the simple substitution of a fuel pressure regulator with a wider range than the stock regulator. As we intended to do later tests with a FI system instead of a carb, we initially left the injectors and all of their wiring in place, but later removed them as they slowed down removing and replacing the system for further modifications and testing.

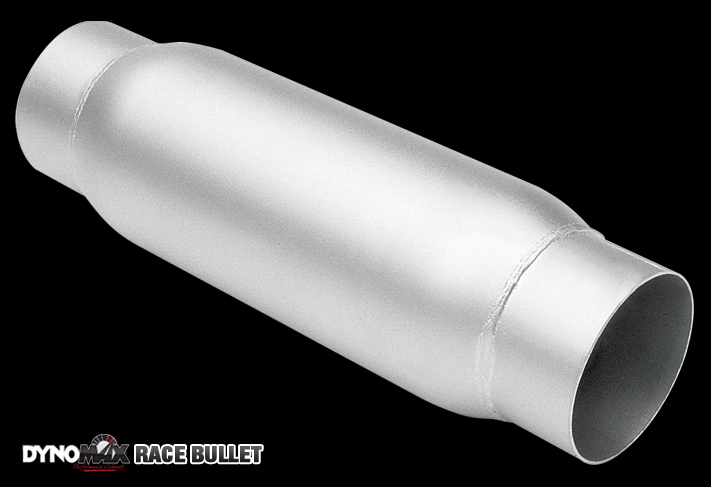

The series of tests on a Superflow chassis dynamometer started with a pre-installation test of the stock 1800ES for a base line. The result of this test was a peak of 111 HP at the flywheel, 90 rear wheel HP, with stock exhaust, air filter, etc. After the supercharger installation dyno tests with the stock D cam and stock exhaust produced increases in the 40 - 50% range, with 150 HP at 6 lbs. boost and 170 HP at 10 lbs. boost being examples. During these tests it became apparent that power was being limited by the restrictions in the exhaust system as further increases in boost produced negligible increases in power.

We then changed to one of our performance heads with modified exhaust ports and larger exhaust valves, short 2.5 inch diameter exhaust, single performance muffler and C cam. The aim for this setup was to exceed 200 flywheel HP - the equivalent of what we get on the vintage race cars on the same dyno. On April 5, 2002 we tested the modified system with the same drive pulley ratio as on the last of the unmodified engine tests. We got 173 HP at the rear wheels, 208 HP at the flywheel, at only 8 lbs. boost. This was an increase of over 30 flywheel HP at 3 lbs. less boost than the test with stock components. Clearly exhaust flow in the stock setup has been a problem. After running for about a month at this boost level the boost was increased to 12 lbs. and our knock sensing timing retard system was hooked up to eliminate detonation problems typically encountered when running at high boost levels. As of the writing of this update, the car had not been dyno tested at this level of boost, but power has increased significantly over the 8 lb. boost level and is estimated to be in the 240 HP range. (If any one would like more details on the dyno tests please e-mail me so that I can send copies of individual tests.)

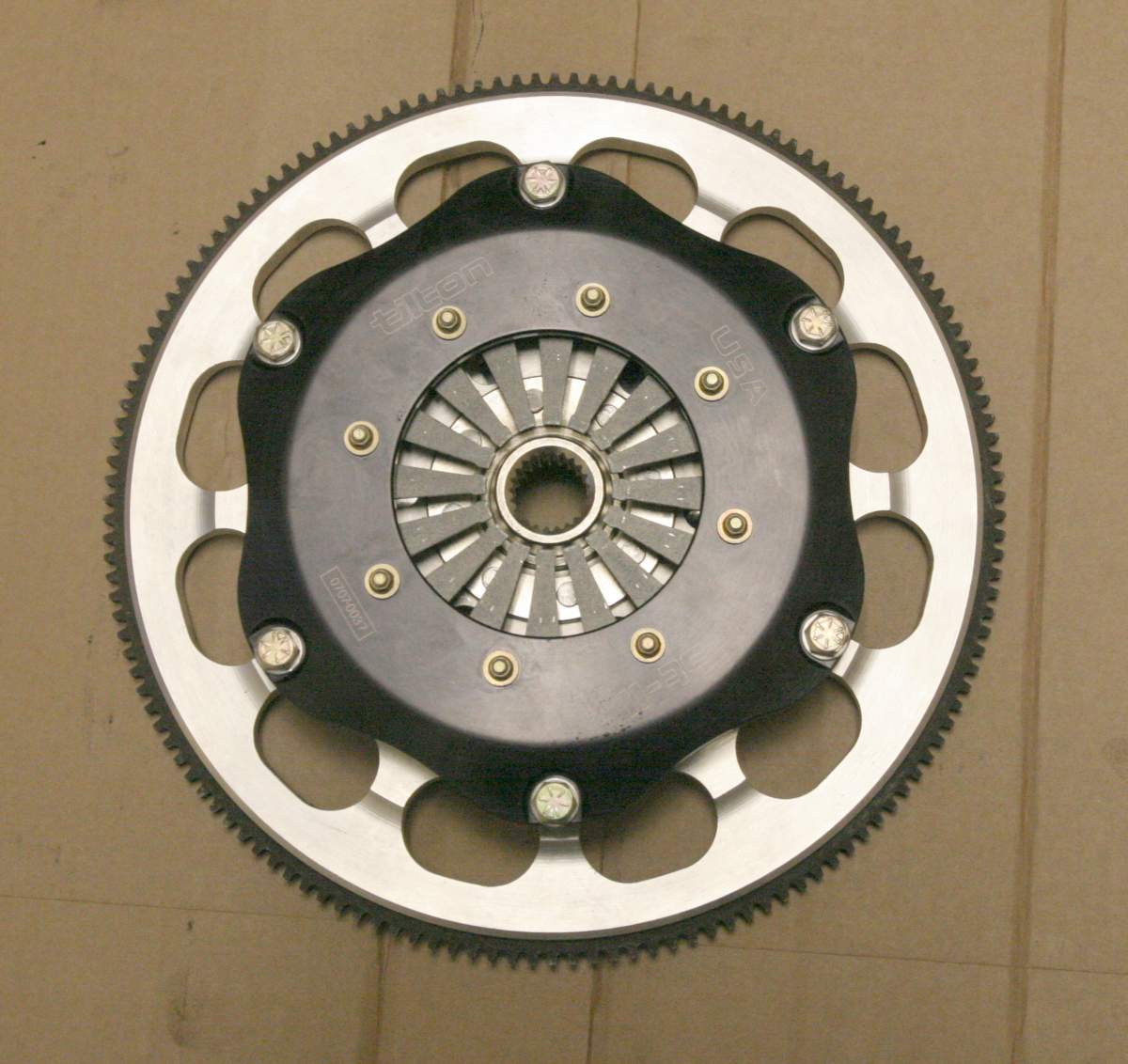

On the road the test car recorded a best 0 - 60 time of 11.8 seconds before supercharger installation. With the supercharger, modified head and exhaust, we were able to do it in under 7 seconds, but clutch slip with the stock clutch limited the ability to launch the car from a standing start. In order to preserve the stock components, further standing start tests were postponed until drive train modifications were made to accommodate power levels over 200 HP. The supercharged test car has been driven daily for over eight months, and has gone on several trips including a 600 mile, one day blast through portions of New England. Even though the trip included some high speed demo miles and vigorous runs through the mountains, fuel mileage on this trip averaged 18 miles per gallon, with 20 MPG being recorded for the NYS Thruway portions.

Significant conclusions from the testing of different configurations are as follows:

- Power increases of 40 - 50% can be achieved at boosts of 6 - 8 lbs. with an entirely stock engine and exhaust.

- No special ignition timing controls are needed with low compression engines at boosts in the 6 - 8 lb. range, but may be necessary for high compression engines - above 9 - 1 compression ratio, depending on level of boost, static timing, tuning, cam, and weather conditions. 4) For boosts over 8 lbs. a timing retard system is needed even with compression ratios as low as 8.5 - 1.

- The stock exhaust system is a critical element limiting the power that can be produced with approx. 170 HP being the power limit for the stock system at boost levels higher than recommended for an entirely stock engine.

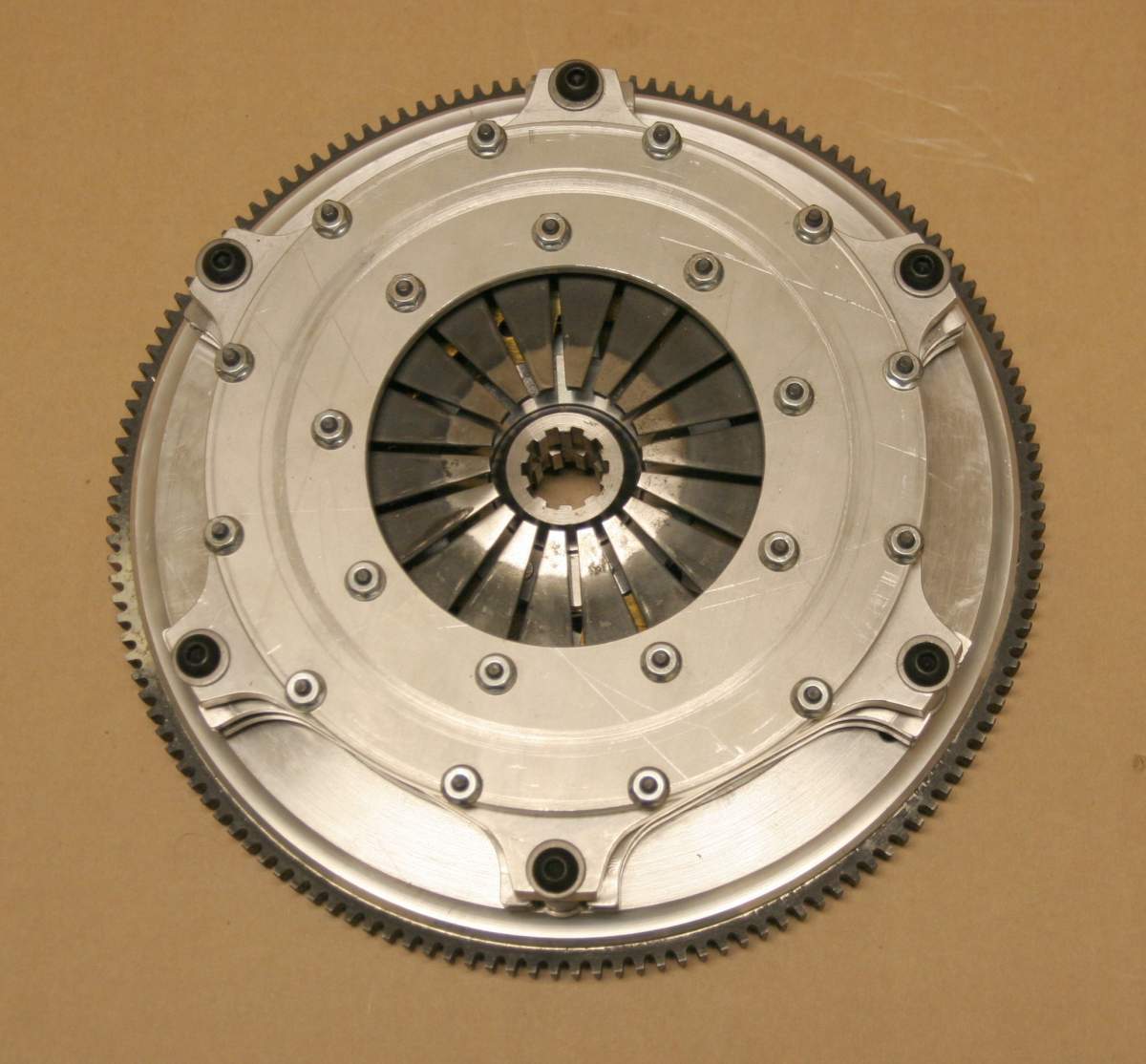

- The stock driveline is adequate for power up to the 200 HP level, but both clutch and overdrive slippage are problems with power above this level.

- The most satisfying configuration includes a free flowing exhaust, modified head, and knock sensing ignition retard system to achieve over 200 HP.

The 200 + HP versions of the system have all of the power I could want on the street. Considering that most early Volvos weigh from 2300 - 2700 lbs., the power to weight ratio of these cars with the supercharger is better than many modern sports cars and sports sedans. In most cases the supercharged Volvo will also have a much broader power band, and this translates not only into ease of driving but better overall acceleration. Coupled to suspension improvements it is probably as close to having my vintage race car on the street as I am going to get, and quite a thrill to drive, especially on the back country roads sports cars were designed for. Hopefully it is a solution for all of those who have said, "I really love my old Volvo, but it just doesn't have enough power."

The results of future tests of the car with modified driveline at even higher boost levels will be posted here as the tests are completed. At this point we are only beginning to explore how much power the system will produce with further modifications.

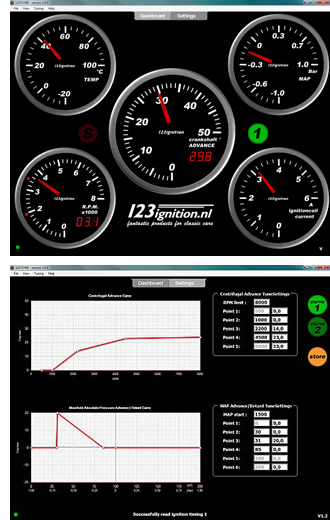

Gauges and Monitoring

We believe strongly in the importance of monitoring engine performance. The 1800ES that is currently being used as the test bed for development of the supercharger system not only has the 1800's normal full compliment of gauges, but also a boost gauge, charge air temperature gauge, intercooler water temp gauge, exhaust gas temp gauges for each cylinder, and a compliment of LEDs. These LEDs indicate the air/fuel ratio and show not only whether there is any detonation/pinging, but also where it is occurring, the frequency and severity. While this type of instrumentation is only necessary for testing, we do recommend that anyone who plans to "push the system" with hard driving and/or engine modifications have water and oil temperature gauges, a boost pressure gauge, and an air/fuel ratio gauge wired to an oxygen sensor in the exhaust system. Using these gauges will assure that the engine is not put under any undue stress and will greatly simplify tuning after the supercharger installation. We can help you by supplying and/or installing any of these instruments.

Upgrades

The basic supercharger system was designed as a bolt-on system that takes advantage of the rugged nature of the B18/B20 family of engines to produce significant increases in power while keeping engine stress within limits that will not jeopardize the renowned reliability of these engines. At recommended boost levels, no engine or drive-line modifications are required for power increases of as much as 50 - 60 %.

However, we recognize that it is in the nature of performance driving (and human nature) not to be satisfied with the amount of power you have, even though it is a lot more than you used to have. With this in mind, we have built into the supercharger system the ability to upgrade for more power without having to change any of the basic components. A smaller supercharger would have been easier to package, but would not have been upgradeable for higher horsepower applications. An intercooler is a highly recommended performance option on most systems but has been built into ours at no extra cost.

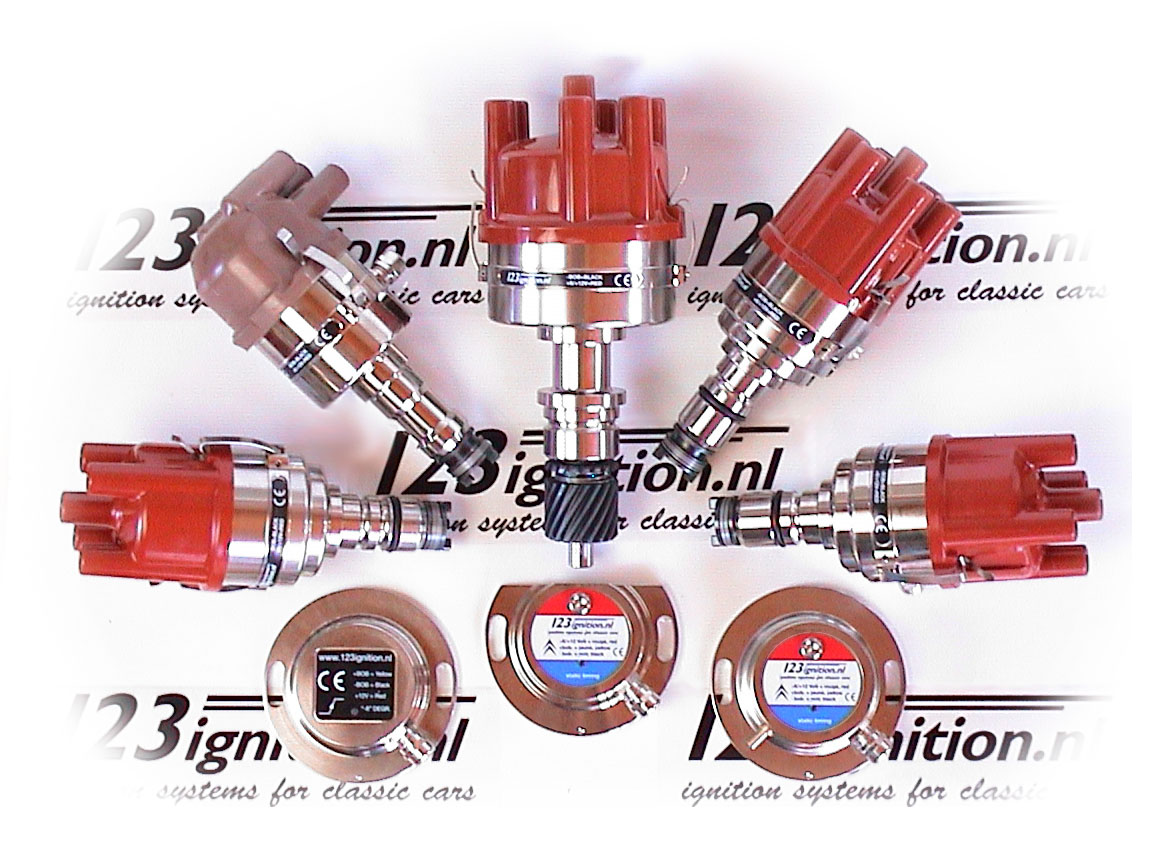

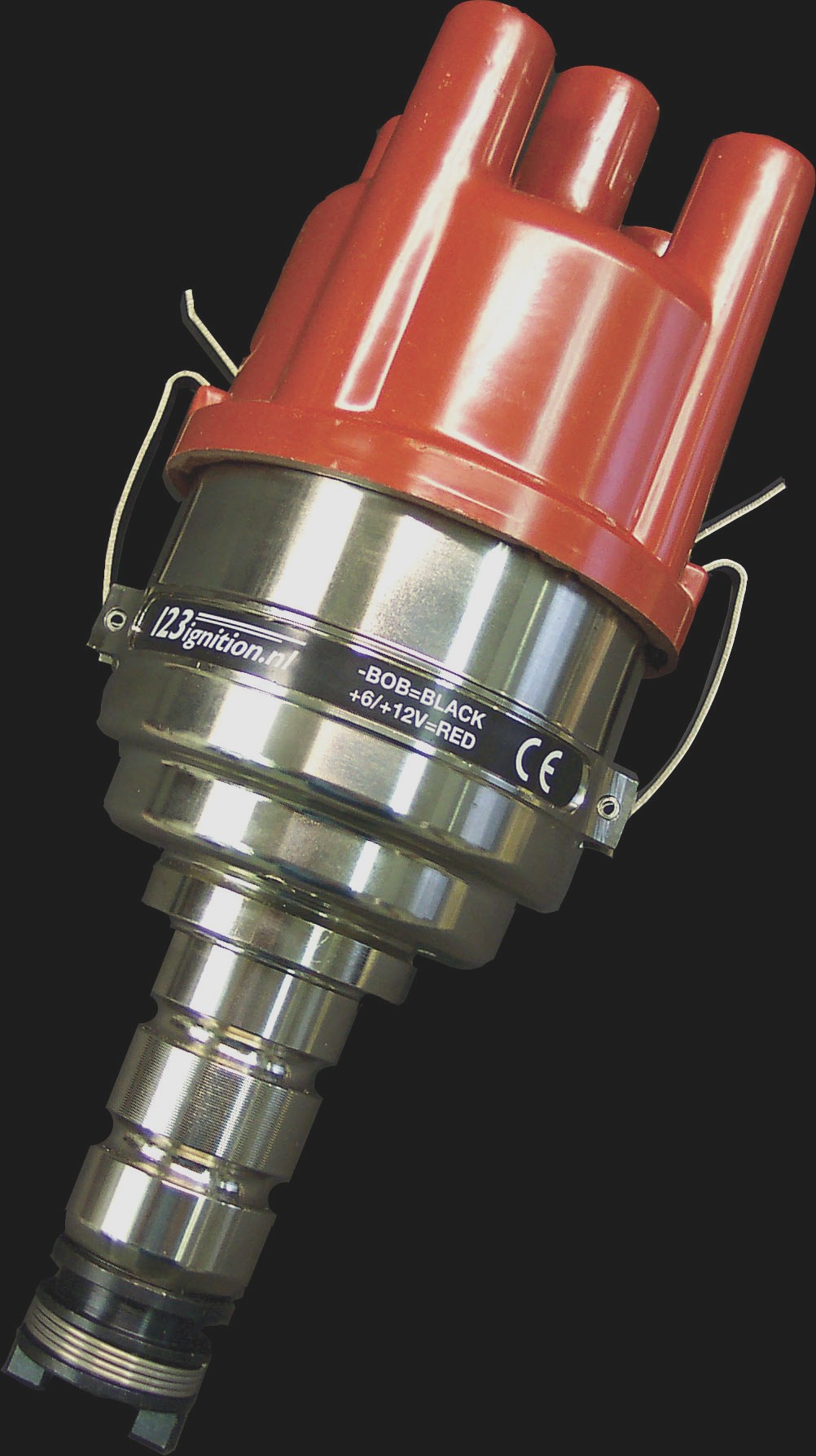

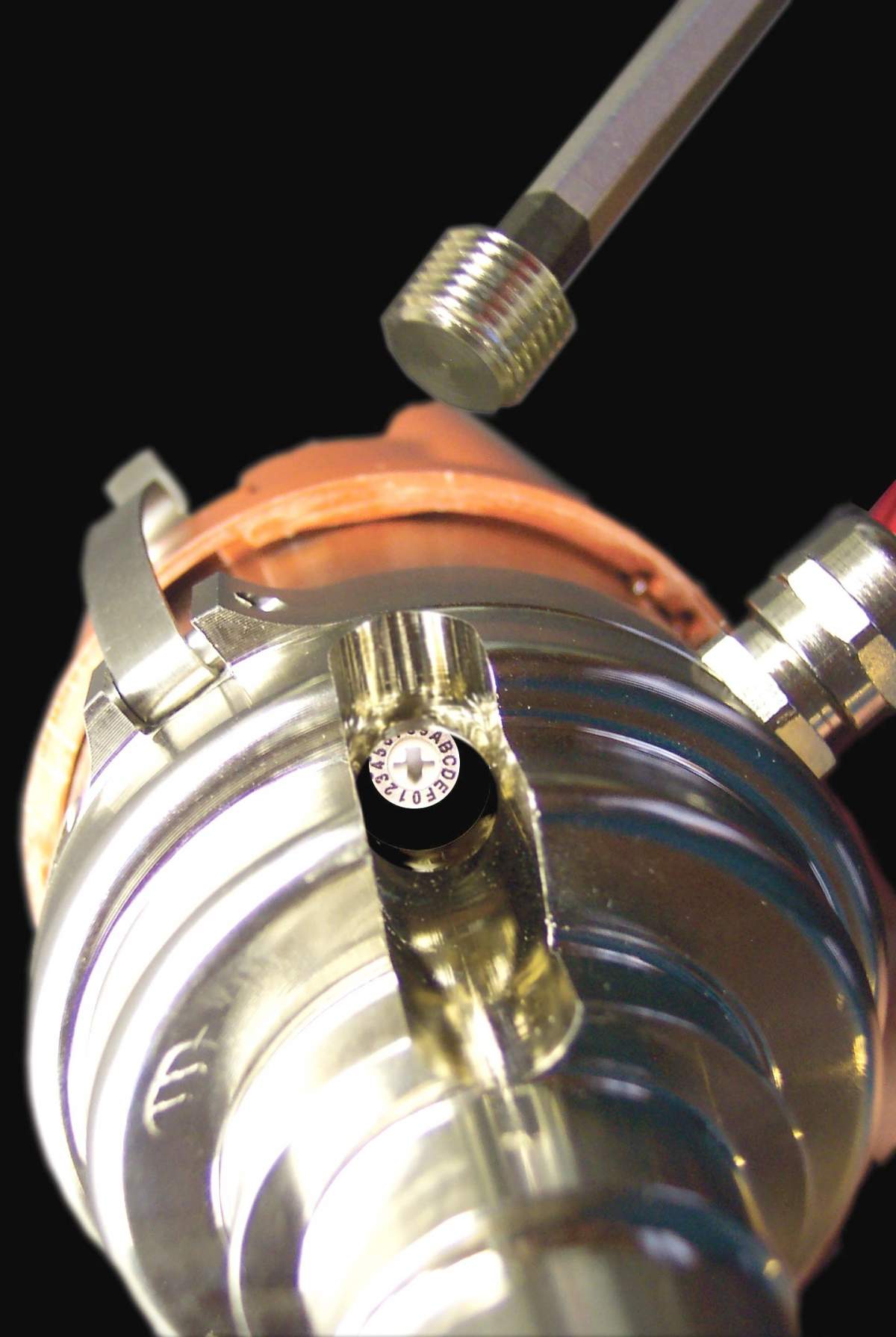

Ignition Systems

Computer controlled ignition systems will allow higher boost pressures to be run by retarding the ignition to prevent detonation. These systems retard the ignition either at a preprogramed rpm, boost pressure, or when detonation (knock) is sensed. We can offer a range of these systems for those want to run higher boost pressures than the standard system.

On our test cars we use a small computer controlled system built by J&S Electronics that senses detonation on an individual cylinder basis and retards the ignition timing to that cylinder only, and then only in the amount necessary to eliminate the detonation in that cylinder. Using this system we have run boost pressures as high as 15 lbs. on a stock engine and expect to go much higher. The system also includes a boost level regulated timing retard, rev limiter, and high output ignition. The current price for this ignition system is $495.

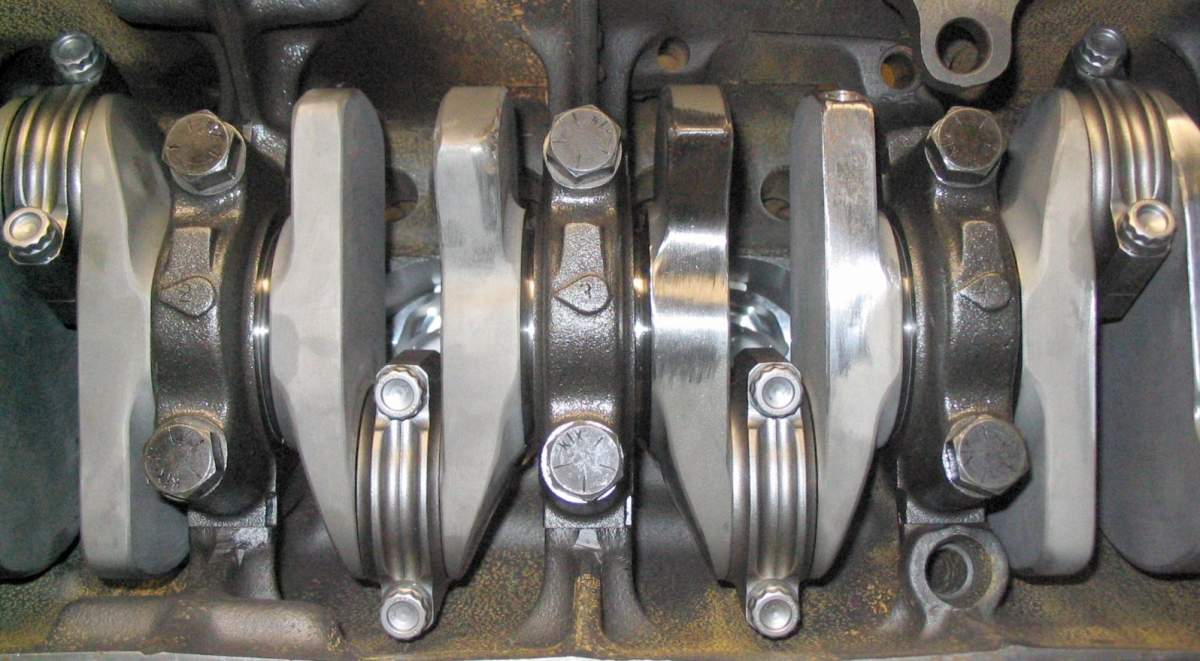

Engines

At some point, the stress that can be produced by high boost pressures is more than can be accommodated by production components. Fortunately, our experience with racing engines puts us in a perfect position to provide the necessary components for ultra high performance applications. Even though our stock test engines have stood up to over 200 HP, we recommend that those who intend to run hard at high boosts do it with an engine rebuilt with forged pistons and other components designed to take considerable abuse. Where appropriate these may include forged pistons, aftermarket connecting rods, etc. See our price list for details on engine options.

Driveline Components

We have been pleasantly surprised that the stock Volvo driveline components have not given us any serious problems with power levels up to 200 HP. However, we are clearly at the point of over stressing these components when we get to the 200 HP level. The problems and solutions are listed below:

• Clutch: At over 200 HP the stock clutch slips in the lower gears. We are currently offering a heavy duty clutch disc that will allow the stock type clutch to work at this power level. We also offer race and rally type aftermarket clutch systems.

• Differential: With an open differential, standing start acceleration as well as cornering under power is limited by the power going to one wheel. A limited slip differential is the obvious cure and we can supply these for most models.

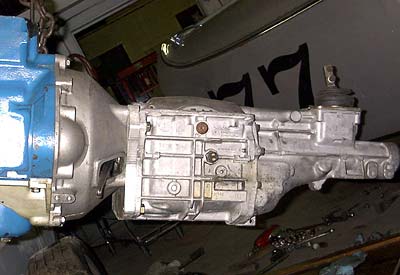

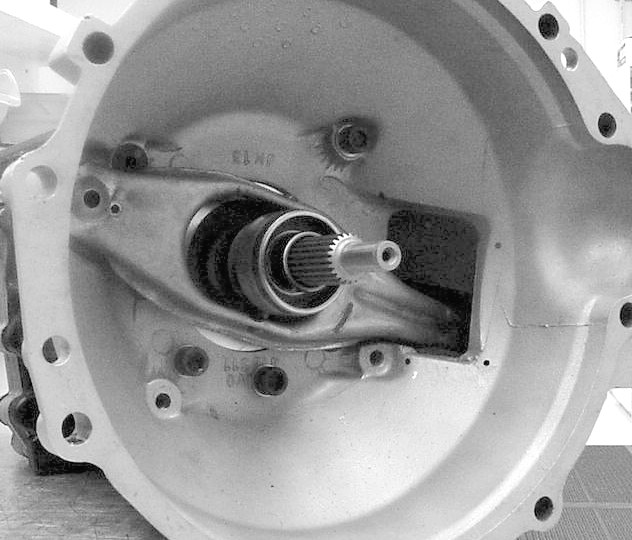

• Transmission: The overdrive slips with sudden applications of power. A transmission swap to a true 5 speed such as a Borg Warner T5 or a Toyota transmission is the answer. Some of these transmissions have an overdrive 5th gear with a lower numerical ratio than the M41 overdrive and should provide for better fuel mileage.

• Gearing: Improvements in fuel mileage as well as acceleration through the gears are limited by the high rear differential gear ratios in the various Volvo models. As these ratios are not needed for low end performance with the supercharger system, a change to a lower numerical ratio is recommended. We can provide different ratio gear sets for most rearends.

Fuel Injection

Research has made it clear that the stock D Jet system will not work with forced air induction systems. However, there are several modern aftermarket, programable fuel injection systems available that can be used to replace the D Jet controller, wiring and sensors, at reasonable prices. Testing on the use of this type of FI system is planned. The supercharger system is designed so that the carb can be replaced by FI at minimal cost and use the stock fuel pump, lines and injectors of the D Jet system. It is expected that both power and fuel efficiency can be improved with a modern FI system.

Over the next year we will do a little playing and see how much performance we can really get out of the system. As we experiment, additional components we be developed and offered to fill your needs.

Suspension

Suspension improvements from VPD

2023 marks the 25th year of our work on Volvo street suspensions. During that time our development and testing produced significant advances in the suspension components available for old Volvos - including a range of custom progressive rate lowering springs and shocks from Bilstein valved to our specifications where required. The only way to "get it right " was to have springs and shocks designed and built to our specifications. Used together, these shocks and springs became the standard options for upgrading the ride and handling of vintage Volvos, with versions designed for use on the street, track, or both.

.jpg) |

After working on race car springs for a while, this was one of the first street cars that we provided a suspension for -in 1998 - based on our progressive rate lowering front springs, which allowed us to provide more control and much better handing, without hurting the ride. |

February 2023 UPDATE - We have some progressive front springs left from prior batches and are looking forward to receiving more with an upgraded specificaiton later in the year. If you need springs, what we have in stock are better than any others currently availalbe. We also have single rate spring sets in stock and rears to go with the front progressives.

The last few years have brought changes in our spring supply and production as he Covid years have to the rest of the inducstry. The company that had been supplying our springs from the begining was reorganized, and then purchased by another company, and no longer able to reliably meet our spring needs. This caused a disruption in supply, and we had to turn to another spring maker to suppliment our supply, and eventually make a new line of springs for us. Unfortunately, rolling out springs with new suppliers has taken much longer than anticipated as it included a period of re- design and pre- production testing of sample springs and then a further disruption caused by Covid. This process is slowly moving forward and we look forward to receiving more of the progressive front springs with an updated specification later in 2023.

While waiting for new springs to become available, we still have plenty of rears and a smaller number ofprogress front springs in stock from previous production runs.

----------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Why you should upgrade your springs and the rest of the suspension as a first step restoring your old Volvo.

If you plan to really use your older Volvo changes to the suspension are needed. Volvo was slow to make the transition to modern handling. Reviewers of Volvos 1960's era cars - from Road and Track, Sports Car Graphic, Car and Driver magazines - agreed that they were typically too high off the ground and had excessive roll in corners - and those were contemporary reviews comparing Volvos to other cars of the same era. These were characteristics that were fine for rough winter roads in Sweden, but not the most appropriate for driving conditions in the US. Today, with faster traffic speeds, improving the suspension is an even more important safety issue. Our suspension components are designed to bring modern handling to older Volvos and are a necessary part of any performance package. Progressive rate suspension springs are a significant advancement over other spring sets offered. Combined with appropriate lowering of the vehicle, attention to suspension bushings, shock absorbers, and sway bars where necessary, the handling of an older Volvo can truly be transformed.

Quick recommendation:

To solve your handling and ride problems - Progressive Rate Lowering Spring Sets, Bilstein Shocks (with custom valving where needed) , and Polyurethane Suspension Bushings

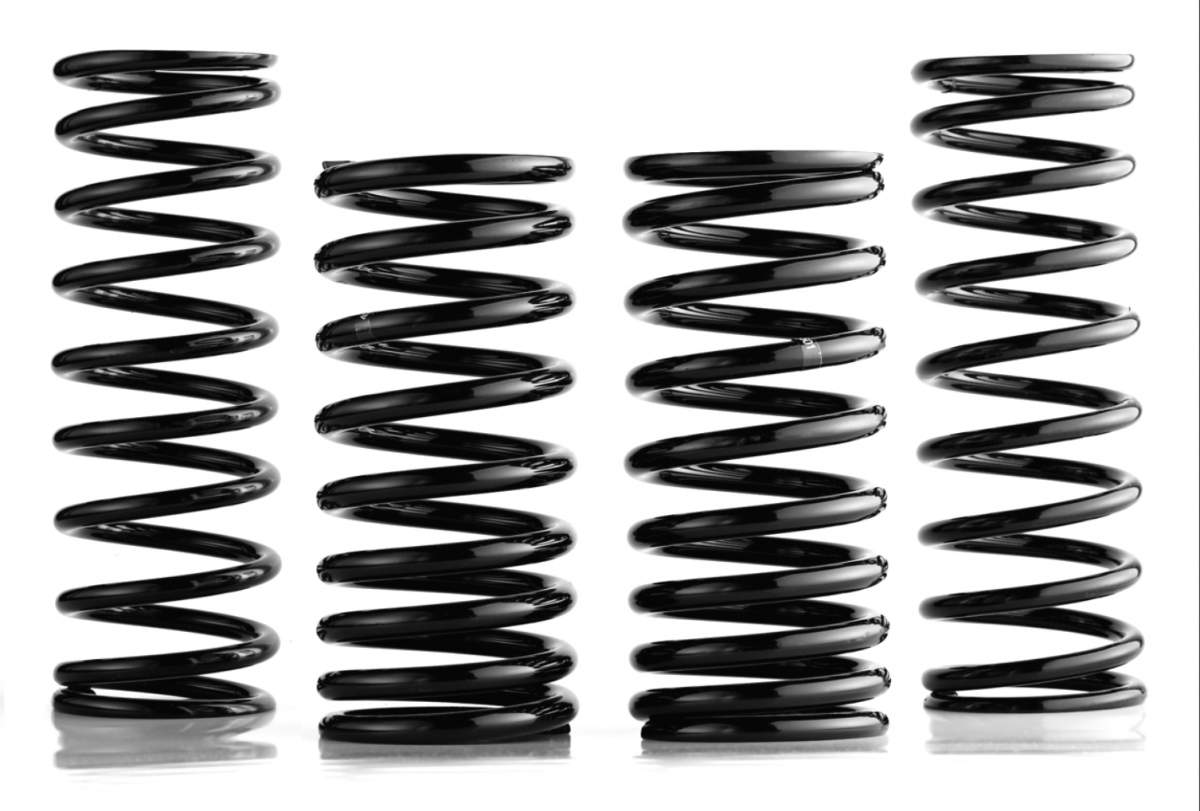

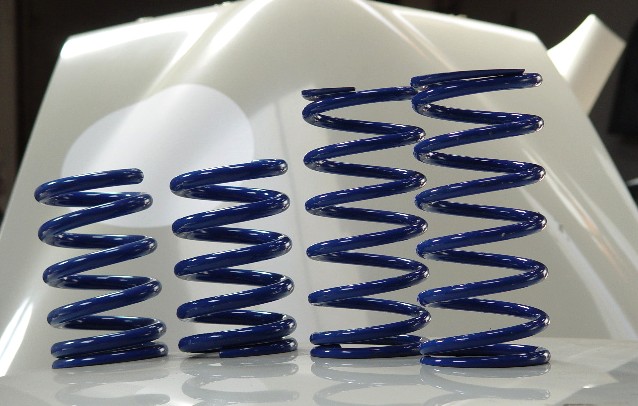

Blue was the standard color for our springs in the past. The newer springs are black as in the photo below of a set.

|

The photo shows one of our progressive spring sets, progressive fronts in the middle, single rate rears to the outside. This is one of our taller sets, shown in black. Brian Harris © 2011.

Suspension Springs

- Springs are the heart of any suspension and have to be changed in order to achieve significant improvements.

- Just adding stiffer sway bars only addresses the cornering roll part of the problem and creates others.

- Lowering the car is an important element in improving the handling as once the center of mass is lowered the suspenision does not have to be as stiff in order to control body roll.

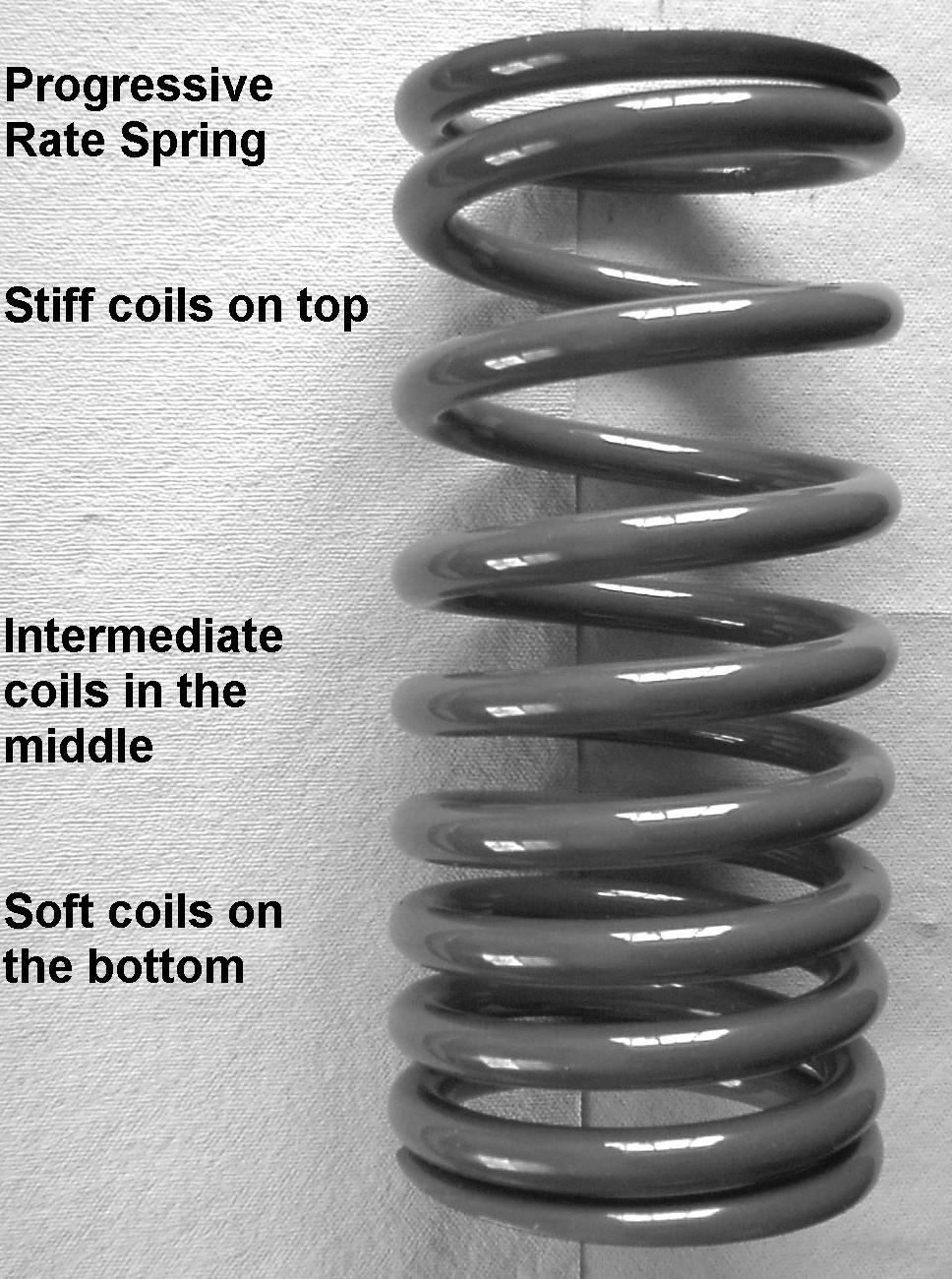

- Progressive rate springs offer a combination of handling and ride comfort that cannot be duplicated by single rate springs.

- Our standard spring package for street or sport for the 122/1800/140 is a lowering spring set with progressive rate fronts and single rate rears designed to lower the car 1 - 1.5 inches from original stock. 122/1800 - $315 140 - $330

- Springs offering lowering greater than 1.5 inches usually available.

Traditionallly most aftermarket suppliers of Volvo springs have only offered one replacement sport spring set for the Volvo 1800/122/140, usually 20% - 30% stiffer than stock and designed for a 1 to 1 1/2 inch lower ride height than stock. These same springs have been offered for over 30 years, and they still have the same problem they have had since the beginning. A stiffer single rate spring improves cornering ability by limiting roll, but the ride quality is adversely affected. In order to keep the ride quality at least tolerable they cannot be stiff enough to improve cornering as much as is desired, but are still stiff enough to give a harsh ride on the street. Quoting Volvo's own R-Sport Performance Parts Catalog, "The shorter and more stiff the spring, the worse the ride becomes." Volvo recognized that the problem could be solved with progressive rate springs, recommended them for all applications where stiffer than stock spring rates were desired, and included them in their suspension upgrade kits. We do the same, and now have a wider choice of ride heights.

Following our lead, other companies are now offering progressive spring sets, but due to their lack of development and testing time have missed the mark in terms of actual performance. If they cannot describe to you their testing and development process and do not know the individual spring rates, then the conclusion as to their quality should be obvious. The specs on our progressive springs are set forth below.

In addition to our progressive rate spring line we still offer traditional single rate street and race performance springs, including a range of springs in different heights and rates to fit individual needs. This allows you to tailor the handling to your driving style and intended use of the vehicle. But unless your use is pure track racing, the progressives are the way to go.

See the customer comments at the end of the suspension section.

Progressive Rate Springs

Soft enough for your daily driver - stiff enough to win the Carrera Panamericana Race - 2009 Historic Class A

-

Progressive 4 spring set for 122 sedan or wagon and 1800 ( progressive fronts - matching single rate rears ). Available in a choice of ride heights. $315

-

Progressive 4 spring set for the 140 and 164 models ( progressive fronts - matching single rate rears ) $330

-

Progressive rate front street springs per pair $170

Single rate springs were the only choice for vintage Volvos before we developed our progressive rate spring sets. Progressive rate springs solve the single rate spring ride quality problem. With progressive springs, to quote the Volvo R-Sport Catalog, "...the rate or stiffness of the spring progressively increases as the spring is compressed... This results in a relatively comfortable ride during normal driving but provides the necessary stiffness for large bumps and hard cornering." For this reason most of the springs offered in Volvo's R-Sport Catalog were progressive rate springs.

The following specifications illustrate how progressive springs are different. Most stock front springs for the 122/1800/140 are in a range close to 250 lbs. to 270 lbs. per inch. Most aftermarket single rate "sport springs" that are offered are in the 320 - 350 lbs. per inch range - not stiff enough for great handling, but stiff enough to hurt the ride. Our progressive rate front street springs are generally in the range of 230 - 250 lbs. per inch for the soft coils and 450 - 500 lbs. per inch for the stiff coils, with intermediate coils in between which progress in stiffness from the soft to the stiff coil range. It is this progression from coils softer than stock to coils that are much stiffer, and how abrupt or gradual the progression is, that allows the same spring to provide both a softer ride and better handling than a single rate sport spring.

Feedback from the hundreds of customers who have tried our progressive springs has confirmed that they offer great handling with a better than stock ride. Most can't believe the improvement. But don't be fooled, all progressive rate springs are not the same. Due to the success of our springs several other suppliers have offered progressive rate springs in the last few years, with very mixed results. They are progressive in the strict sense, but the spring rates are not even close to ours. ( Ask them for specs on their spring rates. ) One set that we tried was so soft that the handling was worse than stock and the ride height was so low that the car constantly bottomed out on the bump stops. So yes, you can now purchase progressive rate springs for a few dollars less, but what is missing is the time spent in design, development and testing in order to "get it right". Our current springs are a 4th generation evolution of our initial design.

Our testing has shown that progressive rate springs are not necessary in the rear and can create other problems, so our 4-spring sets consist of progressive rate fronts matched with single rate rear springs.

We recommend installing our springs with the stock sway bar, and only going to a stiffer sway bar if additional roll control is needed. Sway bars add to the spring rate, and since their action is not progressive, stiff sway bars negate some of the advantages of progressive rate springs. Get it too stiff and the front wheels will loose road contact and tend to skip over small bumps and slide out in rough corners. Where additional cornering control is needed, we offer several choices in sway bar stiffness rather than the "one size fits all " approach of other suppliers. See the "sway bar section" below for details.

Although most "sport " spring sets will lower the ride height between 1 and 1-1/2 inches, we have developed several different progressive spring set combinations. These will accommodate different models, vehicle weights, and customer preferences as to ride heights and type of use. By the end of 2013 we will have added to our spring line progessive sets for the 1800/122 that are both lower ( 2.5 inches lower than stock ) and taller than our standard lowering sets. Combined with the use of spring spacers (shims), they will allow ride heights to be adjusted to a wider variety of individual tastes.

Our progressive rate spring sets have proved to be widely adaptable with uses ranging from street daily drivers, to weekend drives on back country roads, to autocross, trackday and even the Targa Newfoundland and Carrera Pan America Races. In 2009, Richard Bailey won the Historic A Class of the Carrera Panamericana using our progressive spring setup, exactly the same as we offer for street use, together with Bilstein shocks and our polyurethane suspension bushings.

For even more aggressive driving, whether on the street, in a Targa or Carrera race, or in autocross, we can now offer on a custom basis a line of stiffer progressives, specifically designed to be stiff enough to emphasize cornering control, while still having the minimum in soft coils necessary to be tolerable on the street and maintain road contact on corners that are not all racetrack smooth. These springs are for situations where improved cornering performance is more important than a soft ride.

Progressive rate springs are slightly more expensive than single rate springs, approx. $20 more per pair, but are well worth the difference. Most of ourr springs are blue powder coated. Full sets for the 140 and 164 are now available (pictured above). Call, write, or e-mail for details on the appropriate spring set for your application.

Single Rate Street Springs

Where our progressive rate spring sets will not meet a particular need we offer single rate springs that are stiffer and shorter than stock for the front and rear. Street performance sport springs are usually selected to lower the car from one to two inches. (How much the car can or should be lowered is dependent on the wheel and tire combination used, the ground clearance necessary, and the need for sufficient suspension travel.) They significantly reduce body roll and give a stiffer ride. Some spring combinations may require modified mounts. A selection of heights and rates may be available for your model. Contact us for additional details.

-

Single rate street springs per pair 122 and 1800 $150

-

Rear spring pairs for 140, 164, and 240 models $165

-

Rear spring pairs for 122 wagon - several spring rates available - $150

Competition and Race Springs

- Race Springs for Volvo 122 - 1800 & 140 front - $150 per pair for single rate springs

- New front progressive competition springs $160 per pair

- Call or email for prices on other race spring aplications

Offered in custom heights, rates for competition use normally start at 700 lb front, 180 lb rear and go up from there. Most road racers use 800-1000 lb front and 175-225 lb rear in the 1800. Call or email for heights and rates available.

The above photo shows a set of typical Volvo 122/1800 vintage race springs.

The most important thing to note here is that the minimum front spring rate for track use is 3 times the stiffness of a stock front spring, while the rear rate is almost double stock. Race springs also produce a ride height that is usually at least an inch lower than the minimum needed for street use. This means that you really cannot use a competition track spring on the street, or a street spring on the track and expect to be competitive. Several competitors in the Targa Newoundland and Carrera Pan America have used our progressive rate street springs and found that they offer a good compromise where good handling is required but rough roads would rule out the use of a high rate single rate spring. We now offer progressive rate competition front springs.

Some rear springs require modified spring perches or spacers. Adjustable height spring perches are also available. E-mail your individual requirements and I will try to make a recommendation as to which springs would be best for your car.

Typical race car ride hieght is shown above. The ground clearance is less than 4 inches.

Ride Height

How much will our springs lower your car? The answer depends on several factors.

All of our springs are tested with a load. This allows us to create matching pairs and determine which will be a little taller or shorter within a certain range. Determining the affect that new springs will have on your car's ride height is complicated by the fact that on a street car you will most likely be replacing 30 - 40 year old springs that have sagged or settled over the years, depending on the car's use, or lack of use. There were also some variations in spring rates based on model years, and some custom fitting and shimming when the cars were built. Some customers think they have original springs when they were actually replaced by a previous owner at some point. So when we say that our springs are designed to lower a car 1" to 1 1/2", that's an estimate based the original stock ride height and comparing our springs specifications to those of the original springs.

Most important is that the springs are designed to give your car a ride height that will improve its looks and handling while still providing sufficient ground clearance for normal use. For special circumstances we can provide various types of spring spacers in order to customize the ride height.

The photo above shows the ride height with a typical progressive sport spring installation. The ride height is lower in the front than in the rear with the car unloaded, but evens out when loaded. We also offer taller front springsthan on this 1800. Note that the ride height is over an inch taller than on the 1800 race car in the photo above this one.

|

|

Greg Pederson's 122 has taller front progressive springs than the 1800 above, 15 x7 Torque Thrust wheels, and 205/60 tires.

Brian Harris's car shows the ride height of our standard lowering springs with stock size wheels and tires. Brian Harris's car shows the ride height of our standard lowering springs with stock size wheels and tires. |

|

And for those who have questions about whether our lowering springs are appropriate for a car used on city streets, here's a 122 in the Bronx. The owner says:

I purchased your progressive springs and poly bushings last summer and the car has handled amazingly. I've put about 20k miles on it from long highway trips to the terrible NYC roads locally. I've attached a picture of how the amazon is sitting with the new suspension.

Thanks, Julio

|

|

Matt Heckinger wanted to go lower than our standard lowering spring sets, so we provided a set with progressive fronts that gives a ride height approximately 2.5 inches lower than original stock height. His response was: " That's exactly what I was hoping for. Thanks! " We will have a small number of these spring sets by the end of 2013. Get your orders in now.

|

Hi John, here's a photo of my p1800 with your lowered springs and 195mm tires, wow what a better driving car! I got just a little over 1" lowering, looks perfect to me. I was concerned mostly about tire size and fender clearance but with 195mm tires there is no issue and the combination looks great. - Rick Volden

On 9/29/2015 10:36 AM, Rob Barker wrote - Just wanted to write and say thanks for my shocks and springs.

I’ve just completed a tour of Europe and driven 3000 miles in 10 days and the car was an absolute joy to drive. Your springs and shocks are truly amazing and my P1800’s handling is transformed, but yet the ride is still so comfortable and the unbelievable handing is not at the expense of a harsh ride.

Spring Spacers

We offer disc type steel or aluminum spacers ( shims ) for the front of the 1800, 122, and 140, and the rear of the 140, in stock 1/2 and 1/4 inch sizes. Using spacers allow small adjustments in ride height to be made to suit your individual preference or to provide clearance for different tire and wheel combinations. In the front the ride height change will be double the spacer thickness. In the rear the change is the same as the thickness of the spacer. Additional spacers are available in custom sizes.

- New - Aluminum spacers which center on the inside of the springs, front and rear - $22.50 each

- Disc type steel spring spacers/shims - per pair - $ 20

- Disc spacers available for 122, 1800, and 140 front and 140 rear

- Replacement rubber spring spacer cups- front $24.50 each

The Photo below shows one of our disc type spring spacers on the rear of a 142.

Adjustable Spring Height Adjusters

To meet advanced needs we have developed both front and rear spring height adjusters. Some simply slip in with the springs, others must be welded to the chassis. As there are a number of different types depending on the application, please e-mail for details.

Customer Comments on our Suspensions

John,One last thing, you are spot on when you say wait to buy a thicker anti sway bar. I just put Bilstein HD shocks up front and with the new sway bar bushings the stock bar is just fine. No more excessive lean.Your springs coupled with Bilstein HD's make a great suspension package.Edward.

They ride great. Here's an after picture.

Thanks.

Edward.On 4/21/2017 10:46 PM, Douglas Milton wrote:

I put the front progressive lowering springs in and all new bushings and ball joints . I left the heavy sway bar in . The car handles great !! Better than I thought it could. With the bilstiens front and re- valved rears Thanks John I realy enjoy driving that 69 Volvo 1800S.

"On 11/24/2015 4:38 AM, Warren wrote:

I'm very pleased with the new ride height - no longer bottoming out on the exhaust, and the ride and cornering is an amazing difference from the previous progressives that were fitted.

I have just completed my first long drive with the new setup - 900 Km from Melbourne to Sydney (560 miles) in a day, and the 1800 ran like a dream. The ride was secure and wonderfully comfortable.

Thanks again for the great springs, and for selecting a slightly taller set to suit.

Great work. Warren"

On 9/29/2015 10:36 AM, Rob Barker wrote:

Hi John,

Just wanted to write and say thanks for my shocks and springs.

I’ve just completed a tour of Europe and driven 3000 miles in 10 days and the car was an absolute joy to drive. Your springs and shocks are truly amazing and my P1800’s handling is transformed, but yet the ride is still so comfortable and the unbelievable handing is not at the expense of a harsh ride.

On my holiday I was with a group of friends, one of which had a new 911 Turbo and two others who had new Ferrari’s, a 456 Special and an FF. All three drivers couldn’t believe how my little P1800 handled.

Thanks for selling just a great product and for pulling all the stops out to get them to me quickly.

Kind regards,

Rob

( The above was from the UK after participating in the Alpenfahrt Rally )

Hi John, I've been wanting to tell you how pleased I am with your set of springs and how they have improved the looks and handling of my p1800e. In addition, custom wheels and wider tires seemed to put the whole car into better proportion; now I can't stay off the interstate cloverleaf, ha. Thanks, Rick V

1/24/13 8:42 PM

The springs you sold me work great. Much better ride. Rgds. Wilhelm ------------------------------------------------------------------------------------------------------

Sunday, August 19, 2012 11:45 PM

Hi John,

-----------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Wed 6/27 Re: '65 122s progressive rate springs

Thanks for checking up on me. They went in super easy. The directions that you sent were extremely helpful. So far I've got about an hour on them and I can definitely tell a huge difference (It doesn't feel like I'm riding on top of a bobble head any more). I'll give them a few more weeks to settle, but right now it looks like they are about a 1 1/4" lower than it was before. I can see why everywhere I checked said to go with your springs. I'm very happy with them and I know that I will check with you for all my future upgrades/repairs.

Saturday, June 25, 2011 10:44 PM

Subject: Installed my Volvo 122 progressive springs!

John,

The installation was straight forward. Yes, I remembered to remove the

upper cups. I had new upper rubber cushions that I installed.

The new springs sat the car level and about an inch lower. The

progressive springs on the front gives a more compliant ride, especially

with the 1" swaybar. I like them a lot! The lower A-arm is now level

with the ground. Very well engineered.

One suggestion for the front installation instructions... With original

rubber lower A-arm bushings, I loosened the inner bolt to allow the

A-arm to fall freely. Then, with the the new spring in place, I jacked

up the A-arm untill the car was just coming off the jack and tightened

the lower bolt.

http://www.youtube.com/watch?v=OVGZWQ5pBqI&feature=youtu.be

Thanks again,

Gregg

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Wednesday, May 04, 2011 9:00 PM

The 122S handled the Snowball Rally with aplomb. I cannot say enough how pleased I am with the suspension set-up I received from you. Car definitely ran out of power well before it ran of “stick.” You may be getting calls from 1800, 1800ES and 142 drivers who commented on how well the 122 handled and “looked” doing it (very level, with little body roll whether in sweepers or tight corners – which the Sierra Nevada mountains have their share of both). Also there was a very rutted and rocky unpaved portion and the progressive springs worked very well and did not rattle out my fillings.

Thank you. Brad Sullivan

------------------------------------------------------------------------------------------------------------------------------------------------

Hi John, The springs are great! you're right about not needing bigger swaybars; it holds it's own around curves. I'm still trying plan for a supercharger/header combo... I'll just have to see over the next month or so. Mark Mark B. Johnson, Ph.D.

--------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

July 20, 2009

the progressive rate springs and poly bushings ROCK! I chased a 356

> all through the backroads of Norcal once i got them in... much to his

> surprise..!?! Morgan

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

From: sberry <growler@u...>

Date: Mon Nov 22, 2004 11:36 am

Subject: Re: [1800list] Re: go fast goodies was ipd engine stabilizer brace.

-VPD suspension makeover (progressive springs, bilsteins etc.). You can

make the car a very competitive handler for not much money. This recipe

is the best bang-for-your-buck in vintage volvoland IMHO. My 1800 now

handles better than any car I've ever owned.

----------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

The adjustments are made, the car rides and handles like a million bucks.

Thanks for everything. Your product and directions were fantastic.

Dick Sampson

Tucson, AZ

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

To: 'John Parker'

Sent: Monday, December 07, 2009 12:28 PM

Subject: RE: springs

John

They were just perfect.

Happy Holidays

R/jonathan

------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

I installed John Parker's progressive front springs, and the rear springs he

sells which are not progressive. I have Bilsteins, and stock sway bars, and

am very happy with the setup. Nice ride, and when pushed the progressive

fronts come into play. Highly recommended, but check John's site - I don't

think he recommends stiffer swaybars with his spring sets, and I don't know

how the stiffer swaybars would affect the setup.

Installing the springs was easy, takes an afternoon and some creaking for

the first 100 miles as they seat.

David Olson

Œ66 1800s

Œ63 p1800

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

posted by RallyVolvo on Tue Jun 14 12:25 EST 2005

I highly recommend the springs you can get from Parker at V-performance. I've had them on my 71 142E for over a year now, and really like them. Plus they work great for my rallycross habit. :) I also have a 142 built for road racing that is VERY lowerd (as in the 3-4 inches you were talking about) and the front and rear tires are actually up inside the fender openings... And yeah, you would never want to drive that car on the street. Far too low, not to mention a very harsh ride. But it works good as a race car though!

---------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------posted by mike t on Tue Jan 30 02:29 UTC 2007

I am VERY happy with them! Actually we settled on the 175 lb/in. straight rates for the rear. they ride well, but are not a Cadillac ride. They are pretty sporty, but are very well behaved even on broken pvement. Combined with the progressive fronts It is a very nice balance. I can run it ( my 122 wagon ) much harder into corners than in my Skandix progressive equipped 122 coupe.

As you pointed out, the Skandix progressives don't have anywhere near enough spring rate. As soon as the road gets a bit rough, I am into the (already trimmed) front bump stops, which you will agree is a very dangerous business. Good "poser" springs... but not up to spirited driving, especially on "real" roads.

Shock Absorbers

We offer several different types of performance shock absorbers for street and racing use. Whatever brand of shock you choose, it is crucial that the shocks be compatible with the rest of your suspension. In general, a shock with stiffer valving is needed with stiffer springs.

Bilsteins

Bilsteins have been the shock of choice for vintage Volvos for many years and still deserve their excellent reputation. A sophisticated design allows them to provide outstanding handling performance and an exceptional ride. They seem to last forever. Not all shocks can be used on lowered cars, but this is no problem for Bilsteins. They are a good shock for use with a range of springs, and are the recommended shock for our progressive spring sets described above. They last virtually forever and will be last set of shocks you will ever need.

We have found and solved only one problem with the Bilsteins, and this is limited to their current shocks for the rear of the 1800 and 122 where the rebound valving and gas pressure rates are way too stiff - solved by having them revalved by Bilstein to our specs. Its more noticeable in the 1800 which is lighter in the rear than the 122, but still a real issue in either car. The result is a more expensive shock, but well worth the additional cost "to get it right" in a shock that you should have for a lifetime. ( I have over 250,000 miles on a set.) With the custom re-valved rears, there is no question that these are definitely the best shock choice.

We usually stock Bilsteins for 122s and 1800s, and can order them for 544s, 140s and 164s.

-

Stock Bilsteins for most street applications - $425 - $445 depending on application.

-

Bilsteins Custom Revalved to our Specifications for the 122/1800 - Highly Recommended - The rear shocks for these models currently come from Bilstein with valving ( especially the rebound valving ) and gas pressure that is much too stiff for a decent ride and also compromises the handling in all but the smoothest of corners, causing the rearend to skitter over bumps. This has been confirmed by shock dyno tests and comparative data from Bilstein. To solve this problem we went through a series of tests and worked with Bilstein's US Service Dept. to develop optimum valving. As a result, we now have the rear shocks rebuilt by Bilstein to our exclusive specifications. Expensive but worth the extra cost and the only way to “get it right” and have the best handling. They will easily last the life of your car and are the key to having both excellent handling and ride qualities. - $ 650 for a set of four shocks with re-valved rears. $ 430 per pair of re-valved rears.

Please order in advance if you want a set of these custom re-valved shocks. They are re-valved in small batches on a special order basis by Bilstein's US Service Dept. and are often not in stock.

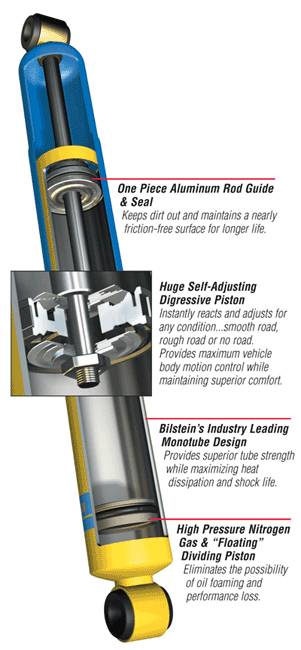

Features of Bilstein HD monotube shocks:

The piston head design allows independent tuning of the compression and rebound damping forces to provide optimum ride comfort and performance without compromise. It features fewer parts than most conventional twin tube and so call "adjustable" shock designs. This simple, yet exceptional functional digressive design contributes to the extreme durability and long life of Bilstein Shock Absorbers.

![]()

|

|

Konis

Back in the 60's and 70's Koni hydraulic shocks were the standard. Several years ago Koni reintroduced these adjutstable hydraulic shocks as their classic shock line. Not as technically advanced as the Bilstein ( hydrualic vs. monotube gas shock with digressive valving), the idea was to bring back the original classic Koni for vintage cars, not update it. They have an advantage over most other shocks in being adjustable to meet your individual needs or compensate for eventual wear. They are long lasting and are an item that you keep and transfer from car to car as I have done on a couple of my street 1800s. ( The Bilsteins are technically superior, but the Konis are a good second choice. )

-

Koni adjustable shocks - Due to recent price increases we no longer stock these shocks - email for availability info.

Race Shocks

-

Race shocks - New shocks are being developed - Email for details

Polyurethane Suspension Bushings

Our testing has shown that polyurethane bushings improve steering response, give a crisp feel to the handling, and reduce the feeling of wandering or floating encountered in high speed cornering with stock bushings. Polyurethane bushings are also not affected by the same causes of deterioration that affect rubber bushings. They are appropriate for both street and race applications.

Our testing has shown that polyurethane bushings improve steering response, give a crisp feel to the handling, and reduce the feeling of wandering or floating encountered in high speed cornering with stock bushings. Polyurethane bushings are also not affected by the same causes of deterioration that affect rubber bushings. They are appropriate for both street and race applications.

Full sets are available for most Volvo models and are usually in stock for 1800s, 122s, 140s and 164s. Email for information on the availability for other models.

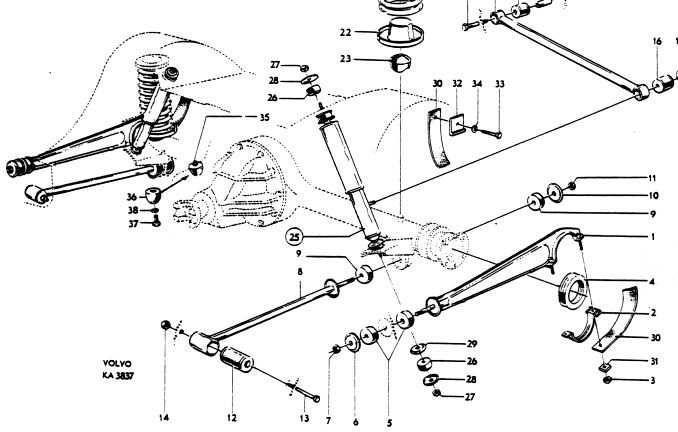

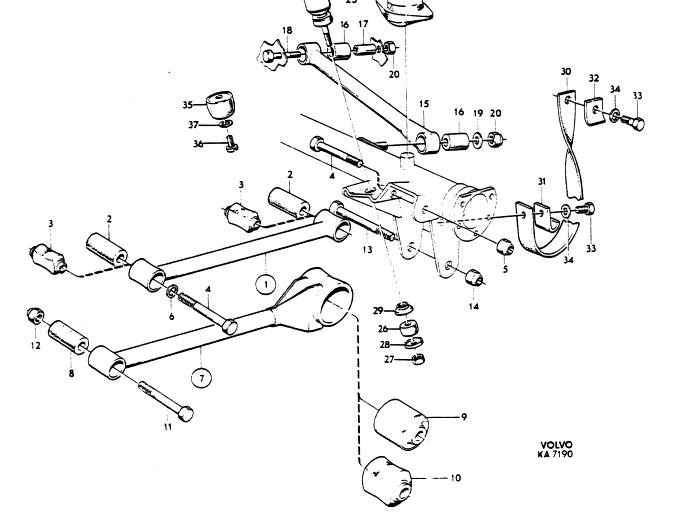

Pictured on the right is a set of bushings for 68 - 73 1800s and 122s.

-

Complete sets for all 1800s, 122s & 140s - All bushings in our sets are poly!

-

Note - Other supplier’s sets are not all polyurethane, are not the same grade of polyurethane & do not include panhard & sway bar bushings

-

early 1800 ( thru '63 ) and early 122 - $ 255 ( same front upper and lower - incl. panhard bar - add $35 for sway bar bushings ) See the diagrams below to confirm which type you have.

-

mid 1800 and 122 - $ 265 ( later type front lower bushhings - early type rear suspension - includes PB add $35 for Sway Bar bushings )

-

122 wagon - later style front lower bushings, all rear in poly, but does not include the square rear trailing arm bush and one end of the panhard bar which are not available in Poly - $195 ( Add $35 for sway bar bushings )

-

67 1800 and 122 - $ 295 square rear bushings ( includes panhard bushings - add $35 for sway bar bushings )

-

68-73 1800 and 122 - complete set $ 295 ( includes panhard bar - add $35 for sway bar bushings ). If ordered separately: Front sway bar bushings - $35. Front upper and lower A arm bushings $97.50. Rear bushings including panhard - $ 205.

-

67-69 140 $ 365 ( includes panhard bar - add $35 for sway bar bushings)

-

70-74 140 $ 465 ( includes panhard bar - add $35 for sway bar bushings )

-

Complete and partial sets available for other models, including the 544, 200, 700, 900 - email for a detailed bushing price and availability information.

See the diagrams and photos below to determine which types of 122/1800 you should order.

.gif) |

|

In the diagrams below the early type 122/1800 rear suspension is on the left, the later type is on the right. The lower photos illustrate the difference in the later type bushing shape - square type 67 bushings on the left - 68 and later "butterfly" shape bushings on the right.

|

|

|

SwayBars

We offer sway bar kits, including IPD front and rear bars, as well as our own adjustable bars in several versions. Different diameters are available in the adjustable bars to be sure that one will be right for your use. Some bars are tubular for light weight and some come with separate bolt-on arms. Adjustable bars are highly recommended for competition use where being able to tune the suspension is necessary. For the discriminating street driver the ability to tune the suspension with sway bar adjustments can be just as important.

We offer sway bar kits, including IPD front and rear bars, as well as our own adjustable bars in several versions. Different diameters are available in the adjustable bars to be sure that one will be right for your use. Some bars are tubular for light weight and some come with separate bolt-on arms. Adjustable bars are highly recommended for competition use where being able to tune the suspension is necessary. For the discriminating street driver the ability to tune the suspension with sway bar adjustments can be just as important.

-

Front / Rear IPD Kit $350 - $375 depending on model

-

Front 1" bar, recommended for the 122/1800 for more aggressive cornering - $165

-

Custom made adjustable tubular bar kits with aluminum arms for race or street. For road race, autocross, or track day use adjustable bars are needed for suspension tuning. Call or email for details and prices.

Engines

Engine Building

Our current Volvo B18/B20 engine designs are the result of over 30 years of dyno, track and road testing.

Unfortunately, we have had to increase prices for 2022 due to increased costs and these increases - mostly about 10% - are not yetreflected in the prices listed below

If you would like to order an engine, fall is usually the best time, but we are still taking orders this spring for summer or fall delivery dependin on the type of engine ordered. And can only hope that supply chain problems will not hold us up waiting for parts as has happened off and on over the last two years. So let us know ASAP if you would a street or racing engine for this year - before we have too many orders and too little time left.

Shown below are some of our chassis dyno - rolling road - test sessions.

|

|

.jpg) |

|

|

In the last 10 years one of the biggest changes here at VPD has been the increased power available from our normally aspirated engines. When we started 140 - 150 HP was typical for a modified Volvo B20 street engine and the only way to get close to 200 HP was in a high compression, high rpm race engine. Then our supercharger kit made it possible to have over 150 HP on an otherwised stock engine and well over 200 HP on the street with a modified B20. This allowed us to offer a street car package for an 1800, 122, 544 or 140 that would give them performance similar to our vintage racecars.

Now, after years of development, we have normally aspirated, large displacement B20 street engines with similar HP and torque as compared to the race and supercharged engines we started with. This gives you the option of having a street engine that looks stock with 170 - 200 HP, more than we used to get supercharging stock engines. On race engines, the larger displacement will produce well over 200 HP, though, as I continually emphasize, a broad power band is more important in any application than peak HP.

As in the past, we continue to provide an engine building service to meet your street, rally and race needs based on over 25 years of experience in these areas. We can rebuild your engine to your custom specifications or supply one based on one of the engine packages outlined below. Engines are available from stock rebuilds to full-out , 8,000 RPM race engines. Check the price list for most recent prices and options. E-mail for additional details. Engines can usually be shipped throughout the US for less than $300 and for less than $600 - $800 to many other countries. Recent engine orders have been from Australia, Germany, Greece, Norway and the UK.

Individual parts can be supplied to assist you in building your own engine, but we are not a parts house and prefer to supply complete systems for best results. We believe in a matched systems approach where the selection of each part in the system depends on the others, and a good match is the key to satisfying performance. This approach is reflected in all of our engines, component kits and our Street Performance Tuning Kit - systems of components designed and matched in such a way that the individual results far exceed what could be achieved throug a seemingly similar combination of individual parts selected by a car owner without the benefit of extensive systematic testing.

Be sure to read " How our engines are different " at the end of the engine section.

Quick Recommendation:

For normal street driving in a Volvo 1800, 122, 544, or 140, our Streeet Performance Engine will meet most needs. For those who want something more, the 2.3 L is the most popular option. It incorporates a significant increase in displacement with a race quality bottom end, tuned as a street engine for torque and a broad power band. See details on all of our engines below.

Volvo B18 - B20 Street Engines